Wood

The Amazing World of Co2 Laser Cutting Wood Techniques

Co2 Laser Technology

At the heart of the laser cutting world is the CO2 laser. A CO2 laser works by stimulating a gas mixture, primarily containing carbon dioxide, with electricity in a sealed tube. This reaction creates a powerful light that is then focused through a lens and directed onto the target material, creating a highly accurate cut, or engraving. For cutting wood, the CO2 laser is an ideal choice because of its versatility in handling different types of wood and its unique ability to produce clean, precise cuts and detailed engravings.

Advantages of Co2 Laser Cutting Wood

Precision & Detail: The laser beam doesn’t wear during the process, which ensures high precision even for very detailed designs. The high level of control allows for complex cut-outs, meticulous engravings, and extremely fine details.

Speed & Efficiency: CO2 lasers can cut through most types of wood swiftly, making it ideal for both small projects and high-volume production. With automated features and computerized systems, the technology allows for less downtime and rapid production rates.

Flexibility: CO2 lasers can easily adapt to various types of wood, from softwoods like pine and cedar to hardwoods like oak and mahogany, even plywood and MDF. It can effortlessly handle varying thicknesses, densities, and sizes with equal precision.

Applications of CO2 Laser Cut Wood

CO2 laser cut wood can be found in a wide range of applications. From industrial production to artistic creations, here are a few notable examples:

1. Furniture Manufacturing.

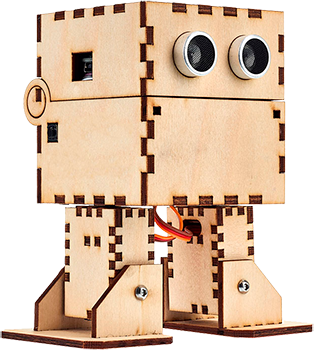

2. Model Making.

3. Art & Decorations.

4. Signage and Displays.

Conclusion

Sample