Customizing a Gun with Laser Engraving

Customizing a Gun with Laser Engraving

The Short Answer: Laser engraving guns allows for precise, permanent customization of firearms through detailed designs, text, and patterns. Professional fiber laser machines can engrave various gun materials safely while maintaining firearm integrity.

Customizing a gun serves multiple purposes beyond aesthetics. Personalized engraving adds unique identification markers, creates brand recognition for gun shops, and allows for specialized marking required by law enforcement and military organizations. Modern laser engraving technology has revolutionized this process, offering firearm businesses a precise, reliable method for adding permanent markings to various gun materials.

Understanding Laser Engraving For Firearms

Types of Laser Technology

Fiber laser and CO2 laser technology offer different capabilities when it comes to firearm engraving. Fiber lasers work by producing a concentrated beam of light that interacts directly with metal surfaces. This makes them perfect for marking and engraving firearms, as they can create precise, permanent marks on metal surfaces without damaging the material structure.

CO2 lasers, while excellent for materials like wood and acrylic, aren’t typically the best choice for gun engraving. Their wavelength doesn’t interact well with metals, making them unsuitable for most firearm applications. Professional gun customization shops typically use fiber laser systems because they produce clean, sharp marks that won’t compromise the firearm.

Firearm Engraving Materials

Most modern firearms are manufactured using various metals. Fiber laser engraving works effectively on all these materials, though the process settings may vary for each:

- Stainless Steel: Responds well to fiber laser marking, producing high-contrast results

- Aluminum: Requires specific power settings to achieve optimal marking depth

- Polymer Components: Can be marked with adjusted laser parameters to prevent material damage

Laser Compatibility

Surface preparation plays an important role in achieving superior quality. The area to be engraved should be clean and free from oils, debris, or protective coatings. While extensive surface preparation isn’t typically needed for fiber laser engraving, some manufacturers recommend light cleaning before the marking process.

The marking depth for firearms must be carefully controlled. If it’s too shallow, the mark may wear away over time. If it’s too deep, it could affect the internal components and structural integrity of the firearm. Professional-grade fiber lasers allow precise control over marking depth, making them a popular option for firearms.

Design Options and Possibilities

Laser engraving ensures crisp, permanent markings that won’t fade over time, maintaining both the firearm’s aesthetic appeal and compliance with identification requirements. Custom logos and artwork allow for truly unique personalization. Common locations include the slide, frame, or barrel.

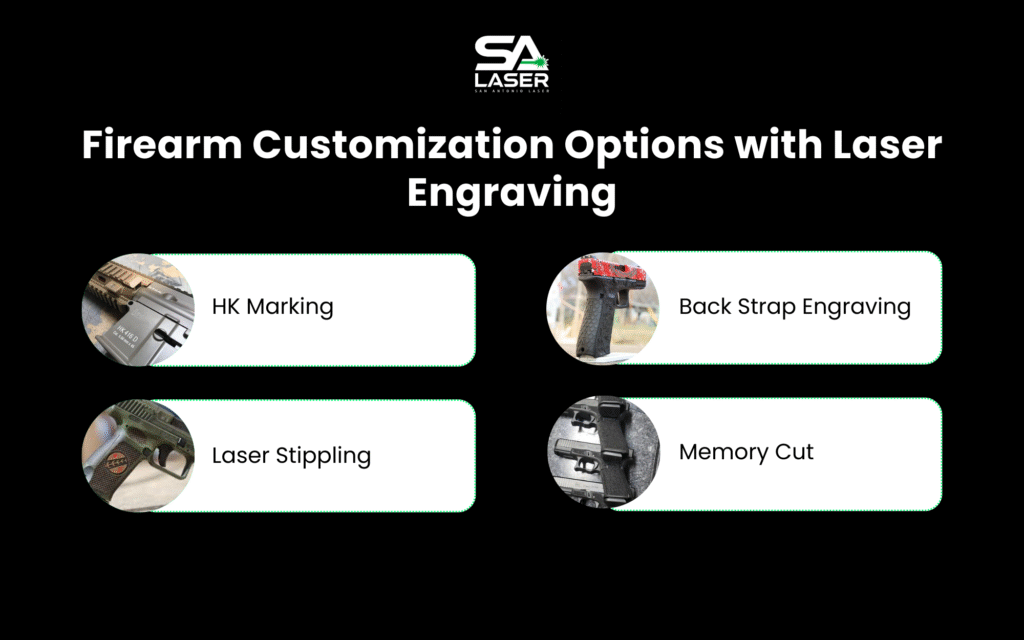

Modern laser systems can reproduce company logos, military insignias, custom artwork, and more detailed images on metal surfaces. Laser engraving offers firearm owners multiple ways to personalize their guns with precision and style. The most common engraving options include:

HK Marking

HK marking is a method used to replicate the authentic factory-style markings found on Heckler & Koch (HK) firearms. These markings can include model designations, manufacturer information, proof marks, and serial numbers. High-precision laser engraving technology allows for HK markings applied with exact depth, font, and placement to match original specifications. This process is ideal for restorations, clone builds, or enhancing the authenticity of custom rifle, pistol, or shotgun projects.

Text and serial numbers remain the standard choice for practical identification. Professional engravers can add serial numbers, names, contact information, or meaningful quotes in various fonts and sizes.

Back Strap Engraving

Back strap engraving transforms the rear portion of a firearm’s grip into a canvas for personalization. These tactical-style embellishments not only elevate the firearm’s visual appeal but can also provide subtle texturing for improved grip and handling. Popular choices include scrollwork, geometric patterns, and tactical-style embellishments that complement the gun’s aesthetic while maintaining a professional appearance.

Laser Stippling

Laser stippling uses precision laser engraving to create textured patterns on firearm frames, improving both grip and aesthetics. Unlike traditional hand stippling, laser stippling produces consistent, repeatable designs with exact depth control, allowing for intricate patterns, logos, or custom artwork. Handgun and Glock stippling not only provides a more secure, slip-resistant surface but also offers a professional-quality finish and endless design possibilities for personalization.

Memory Cut

A memory cut refers to the second part of a notorious “double undercut” modification on modern polymer-frame firearms. This precise cut, which is not allowed in many competition shooting events, provides a reference point for the support hand and knuckle. Using laser cutting for a memory cut ensures exact placement, clean edges, and a professional finish without compromising the firearm’s structural integrity.

Metal Etching

Metal etching uses laser engraving techniques to create detailed markings, patterns, and designs on a gun’s metal surfaces. Etching can range from deep engravings to lighter surface markings, depending on the desired effect. By offering a durable, corrosion-resistant finish that stands up to regular handling and use, the method is a popular choice for custom guns.

Design Considerations

When planning your firearm engraving project, several technical factors affect the final result:

- Size & Placement: Engraving requires careful planning of the device and the product’s dimensions to find the perfect fit.

- Location: The engraving area must work with the gun’s contours while remaining visible. Placement should never interfere with the firearm’s function or safety features.

- Resolution & Detail: These detail limits depend on the laser system’s capabilities.

- Spacing: Intricate designs need proper spacing to maintain clarity.

- Text: Small text may become illegible, while oversized text can appear disproportionate.

Safety and Legal Requirements

Licensed manufacturers and dealers must maintain detailed records of all laser-engraved firearms, including the original serial numbers and any additional markings added. The records should document the date of engraving, the specific modifications made, and the identity of both the firearm owner and the person performing the work.

Regulatory Compliance

When laser engraving firearms, federal regulations set strict guidelines that must be followed. The Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) requires all serial numbers and identifying marks to be permanently engraved to a minimum depth of .003 inches. These markings must include the manufacturer’s name, model, caliber, and serial number on the frame or receiver.

Best Practices

Proper machine operation starts with practicing safety and efficiency before beginning an engraving project:

- Operators should wear appropriate protective gear, including safety glasses designed for the specific wavelength of the laser being used.

- The work area must have adequate ventilation to remove any fumes or particles created during the engraving process.

- Engravers should be thoroughly trained on the laser engraving equipment they’re using.

When handling firearms for engraving, follow these guidelines throughout the process:

- Verify the firearm is completely unloaded before beginning work

- Use appropriate fixtures and clamps to secure the firearm during engraving

- Clean the engraving area thoroughly to remove any oils or residue

- Test the engraving settings on similar material before working on the actual firearm

- Use calibrated measurement tools to verify engraving depth meets ATF requirements

- Inspect completed markings to confirm proper depth and legibility

- Document all quality checks in your records

- Maintain samples of successful engravings as reference standards for future work.

Having proper procedures in place for both routine operation and emergency situations will help protect operators and maintain consistent engraving quality.

Trust SA Laser for Your Laser Engraving Needs

Incorporating laser engraving services in your business requires professional-grade equipment and expert support. As a veteran-owned company with over a decade of experience, SA Laser delivers both. Our heavy-duty fiber laser machines effectively meet many different needs for laser engraving success.

SA Laser is the only laser manufacturing company with a Federal Firearms License (FFL) and a Special Occupational Taxpayer (SOT) designation. We’ve set ourselves apart with our Edge Series and our industry-leading Spark™ Training Program, offering all the support you need to master firearm engraving techniques like stippling and NFA markings.

Beyond equipment, SA Laser provides specialized services for firearms, including precise NFA engravings and laser stippling. Our expertise comes from years of hands-on experience as engravers. With over 800 successful laser engravers as clients, SA Laser has built a reputation for excellence in several industries.

Ready to update your engraving capabilities with firearms customization? Explore our laser engraving machines, industry-leading Spark™ Laser Training, and must-have laser accessories.