Laser engraving has become one of the most versatile, reliable, and cost-effective tools for small businesses looking to expand product offerings, strengthen branding, and provide customized services. Whether you run a retail shop, online store, engraving service, or promotional products business, adding a laser system can open doors to new revenue streams, streamline production, and help you stand out in competitive markets. Here are five practical ways laser engraving can help your small business grow and succeed.

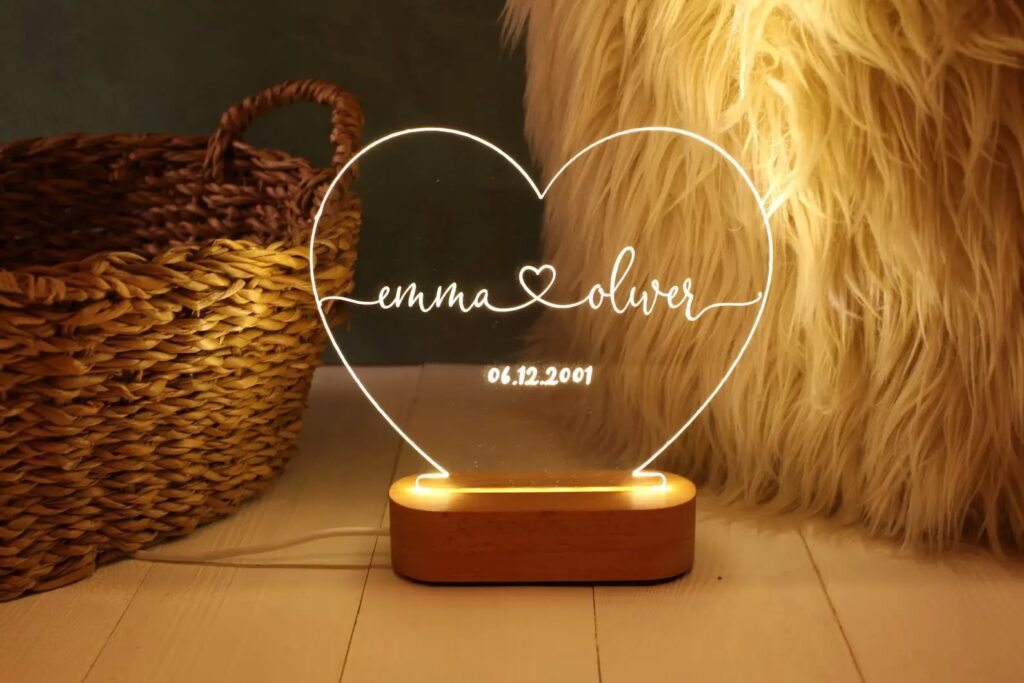

Personalized products continue to be a top-selling category across retail, e-commerce, and gift markets. Laser engraving allows small businesses to create a wide variety of custom items—everything from engraved tumblers, cutting boards, and drinkware to signs, coasters, keychains, awards, and plaques. Even small touches, like adding a customer’s name or a special date, make products feel personal and memorable.

Personalized items encourage repeat purchases and referrals because customers are more likely to share something unique with friends and family. For example, a small business selling engraved wooden cutting boards for weddings or anniversaries can see consistent demand year-round. Adding customization options doesn’t have to be complicated either—modern laser systems can handle everything from one-off orders to bulk runs efficiently, making personalization accessible for businesses of any size.

Your branding goes beyond a logo or a website—it’s the overall experience customers have with your business. Laser engraving makes it simple to produce high-quality signage, nameplates, display pieces, branded merchandise, and point-of-sale displays that reinforce your professionalism. Engraved signs for your storefront, office, or trade show booth can make a huge difference in how your business is perceived. Materials like wood, acrylic, metal, and leather offer endless possibilities for customization. You could create sleek engraved desk signs for corporate clients, rustic wooden menus for a café, or professional awards for local businesses. Each engraved item is durable and visually appealing, creating a polished impression that builds trust.

Flexibility is one of the strongest advantages of laser engraving. A modern laser system can handle both one-off custom orders and larger batch production with ease. This opens opportunities for businesses to accept personalized or niche orders without dramatically increasing labor costs.

For instance, a small business offering engraved promotional items can quickly switch between products and designs, from custom keychains for a local event to engraved awards for corporate clients. The precision of a laser system ensures that every product is consistent and high-quality, even when producing large quantities. This allows small businesses to expand their offerings, enter new markets, and test product ideas with minimal financial risk. The ability to efficiently handle custom orders can set your business apart, creating a reputation for reliability and quality that customers will trust.

Community events, craft fairs, trade shows, and promotional events are excellent opportunities to connect with potential customers. Laser engraved products naturally stand out in these environments because of their quality and uniqueness. Items like custom ornaments, branded keychains, badges, plaques, and giveaway products can attract attention and create a professional, memorable presence.

For example, a small business selling engraved drinkware at a local craft fair can offer on-the-spot personalization, giving customers an experience that feels interactive and special. Engraved products also act as long-lasting promotional tools, reminding customers of your brand long after the event. By investing in distinctive, high-quality products for events, small businesses can maximize exposure and create meaningful connections with potential buyers.

Laser engraving offers unmatched versatility, allowing small businesses to work with a broad range of materials—including wood, acrylic, coated metals, leather, glass, and select plastics. This versatility makes it easy to introduce new products or test market demand without significant upfront costs. From home décor and personalized accessories to corporate gifts, awards, and custom signage, a single laser system can support dozens of product categories.

Small businesses can experiment with different materials, designs, and product types while minimizing waste and production errors. For example, a business could start with small, personalized items like engraved coasters and gradually expand into larger, more complex products such as wooden signage or metal awards. This flexibility allows businesses to grow strategically, diversify their offerings, and increase revenue without large investments in new equipment or manufacturing processes.

Adding laser engraving to your business workflow opens the door to new products, stronger branding, and expanded customization capabilities. With its precision, versatility, and ability to handle both simple and complex designs, laser engraving provides small businesses with a reliable way to upgrade services, increase efficiency, and generate additional revenue. For business owners ready to take the next step, SA Laser offers comprehensive online training and resources to guide you step-by-step, ensuring you can implement laser engraving successfully and confidently.

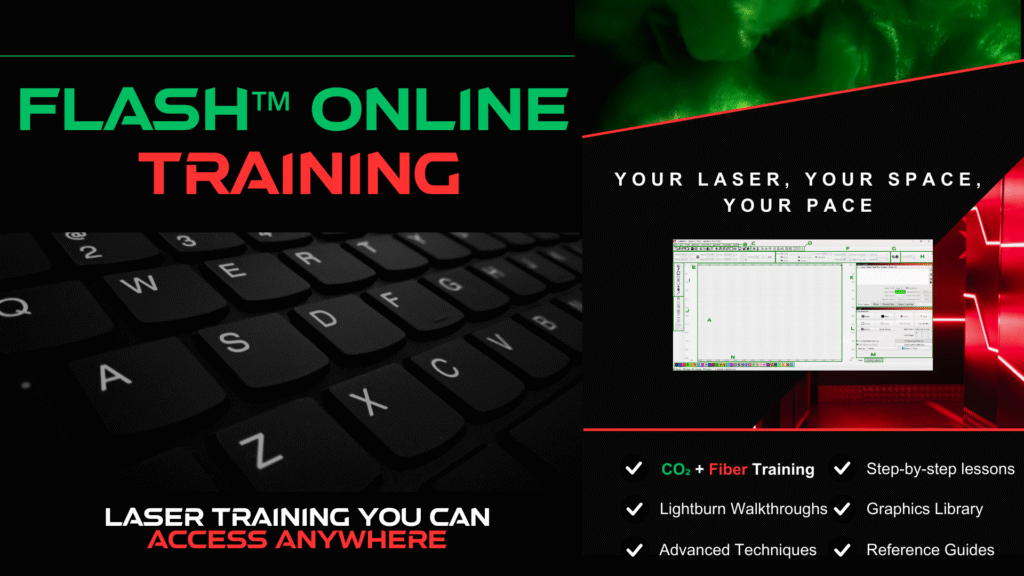

Mastering laser engraving has never been easier. With SA Laser’s online learning platform and Flash Fiber and CO2 laser training, you can gain real skills at your own pace, from the comfort of your own home. The platform provides structured instruction, hands-on exercises, and expert guidance designed to help you succeed, all while connecting with a community of fellow laser enthusiasts who share tips, projects, and encouragement.

Online learning gives you flexibility and efficiency that traditional classes cannot match. Lessons are broken into short, easy-to-follow videos, so you can absorb the material without feeling overwhelmed. You can revisit any lesson as often as needed and immediately apply new techniques on your own laser system.

If you’re looking for a place to learn laser engraving while connecting with other engravers, our online learning platform was built exactly for you. It gives you a space to explore new techniques, improve your engraving skills, and understand your machine with clarity. You get the benefit of guided learning while still working from home, and the added support of other learners who share your passion. This combination makes the entire learning process feel natural, organized, and approachable for anyone ready to grow.

Every course is taught by instructors with real experience in CO2 and Fiber laser systems. You learn practical skills that make an immediate difference in the quality of your engraving. Lessons walk you through settings, techniques, troubleshooting, and project setup in a way that feels organized and intentional. Students often mention how quickly they gain confidence because the instruction is clear, direct, and rooted in real engraving workflows. This level of detail is especially valuable for beginners who want reliable laser engraving guidance instead of guessing which settings to use.

These courses are built to help you avoid mistakes, understand why certain results happen, and work smarter with your machine. You get to learn in a way that supports your schedule and progress. With consistent explanations, visual demonstrations, and real life examples, you develop a deeper understanding of how CO2 and Fiber lasers behave on different materials. This helps you improve your technique, solve problems faster, and create cleaner, more professional engravings.

On our LaserHeads platform, you’ll find full CO2 laser courses, Fiber laser courses, and complete LightBurn training. Everything is broken down into modules that guide you from foundational skills to more advanced engraving techniques. You can learn LightBurn layout tools, material testing, engraving presets, file preparation, and settings optimization in a way that makes sense even if you have never used design software before.

The combination of expert guidance, hands on practice, and a connected learning environment helps you build skills that lead to consistent, professional results. You’ll learn settings, materials, layout, focus, project organization, and complete engraving workflows you can use right away. The courses are structured to teach you how to develop repeatable results, improve your engraving clarity, and understand why each adjustment matters. Over time, these methods help reduce material waste, cut down your trial and error process, and increase your overall confidence with your laser system.

If you want something more immersive, SA Laser offers a five day in person Spark™ training experience at our facility in San Antonio, Texas. This course gives you direct feedback, live demonstrations, and guided practice time that helps you grow faster. It covers machine setup, material handling, engraving techniques, software skills, and workflow strategy in a way that accelerates your confidence and your results. The in person experience allows you to work closely with instructors, see how different techniques behave in real time, and ask questions as they come up.

Your success is the heart of every course. These lessons are designed to help you apply new techniques quickly, understand your machine fully, and learn without feeling overwhelmed. You get the benefit of expert instruction, structured learning, and the support of a community that celebrates your progress with you. It creates a learning environment that feels encouraging, productive, and genuinely enjoyable. Each course is made to help beginners build confidence and give experienced users a clearer understanding of advanced engraving techniques, all with practical examples you can use right away.

These courses help you elevate your craft, grow your business, improve your workflow, and feel confident in every project you start. With a mixture of video training, hands on materials, LightBurn instruction, and community support, you build the kind of long term knowledge that improves both creativity and production quality.

Experience the convenience, clarity, and community of SA Laser’s online learning platform. Explore the courses, watch previews, and start learning at your own pace with support that stays with you. You get a full library of laser engraving education designed to help you improve step by step and grow steadily.

Launching a laser engraving business can feel out of reach if you’re worried about upfront costs. The truth is, you can get started without a large initial investment. Through SA Laser’s trusted financing partners, Clicklease and Geneva Capital, you can launch your engraving business with no money down and flexible payment options that fit your goals.

Geneva Capital offers a standout financing opportunity: no payments for three months, affordable fixed payments, and potential tax benefits under Section 179, all with quick approvals. This makes it easier than ever to invest in professional-grade CO₂ or fiber laser systems without straining your budget.

Geneva Capital has introduced a special term promotion exclusively for SA Laser clients. Catering to a range of credit situations from Good to Excellent. Those with top-tier credit can especially benefit as they're entitled to make ZERO payments for the initial 3 months.

One of the biggest hurdles when starting a laser business is equipment cost. That’s why SA Laser partners with Geneva Capital and Clicklease to make financing accessible and straightforward. Both offer quick approvals and affordable monthly payments designed for new entrepreneurs.

Clicklease works with a wide range of budgets and credit profiles, while Geneva Capital’s no-money-down program gives you three months payment-free to produce, sell, and build revenue before your first bill is due.

If you’re starting from scratch, our Business Starter Bundles are also a great solution. They combine a laser system, essential accessories, and training in one easy-to-finance package—helping you launch your business with confidence and minimal upfront costs.

Geneva Capital has introduced a special term promotion exclusively for SA Laser clients. Catering to a range of credit situations from Good to Excellent. Those with top-tier credit can especially benefit as they're entitled to make ZERO payments for the initial 3 months.

Clicklease offers fast approvals and affordable payment plans designed for small business owners. Just fill out the financing application, which takes less than five minutes and gets you one step closer to launching your business.

When you finance through Clicklease or Geneva Capital, you can invest in the right machine without waiting months to save. Both partners offer flexible payment options that make it possible to start now and grow at your own pace.

CO₂ lasers are perfect for creative entrepreneurs who want to work with wood, acrylic, leather, glass, and certain plastics. They’re ideal for personalized products like signage, décor, and promotional gifts. With affordable monthly payments, you can start producing right away instead of delaying your plans.

Fiber lasers are built for high-precision metal engraving. They’re great for industrial marking, personalized tools, and firearm components. Financing lets you enter these profitable markets without the heavy upfront cost that stops many small businesses.

With SA Laser’s financing partners, you can start with the machine that fits your current goals and add another system later as your business expands.

Before investing in software or paid courses, take advantage of free resources to sharpen your skills. Trial versions of design programs like LightBurn allow you to explore workflows before purchasing a license. You can also find free online templates, video tutorials, and guides that help you practice engraving techniques and project setups.

Learning from community creators, YouTube educators, and design forums can give you valuable insights while keeping expenses low.

After your laser is up and running, it’s time to get your work noticed. With no money down financing, you can put more of your budget into marketing instead of large upfront costs.

Start small by showcasing your designs on Instagram, TikTok, or Pinterest. Post process videos, before-and-after shots, and finished projects to attract new customers. You can also network locally by collaborating with small businesses or offering custom samples for events.

Financing through Clicklease or Geneva Capital gives you financial breathing room to invest where it matters most — growing your audience and building momentum.

Starting with no money down means you can take manageable steps without financial pressure. Begin with simple, high-margin products such as engraved tumblers, signs, or keychains to build your reputation and generate revenue quickly.

As you grow, reinvest your profits into upgrades or additional laser systems. Both Clicklease and Geneva Capital offer flexible options for scaling when you’re ready to expand.

Geneva Capital’s current opportunity makes it even easier to get started. You’ll pay nothing upfront, make no payments for the first three months, and benefit from fixed monthly costs and fast approvals. It’s an affordable way to focus on production, marketing, and building your brand before your first payment is due.

When you partner with SA Laser, you’re not just buying a machine. You’re gaining access to financing, training, and community support that set you up for long-term success.

Starting a laser engraving business doesn’t have to be expensive or intimidating. With SA Laser, Geneva Capital, and Clicklease, you can begin building your dream business with no money down, no stress, and full confidence in your growth potential.

Geneva Capital has introduced a special term promotion exclusively for SA Laser clients. Catering to a range of credit situations from Good to Excellent. Those with top-tier credit can especially benefit as they're entitled to make ZERO payments for the initial 3 months.

Clicklease offers fast approvals and affordable payment plans designed for small business owners. Just fill out the financing application, which takes less than five minutes and gets you one step closer to launching your business.

The Short Answer: A laser engraver can generate income through multiple business models, including custom product creation, service-based engraving, and specialized niche markets. With proper training and the right equipment, laser engraving businesses can serve various industries from awards and trophies to industrial marking.

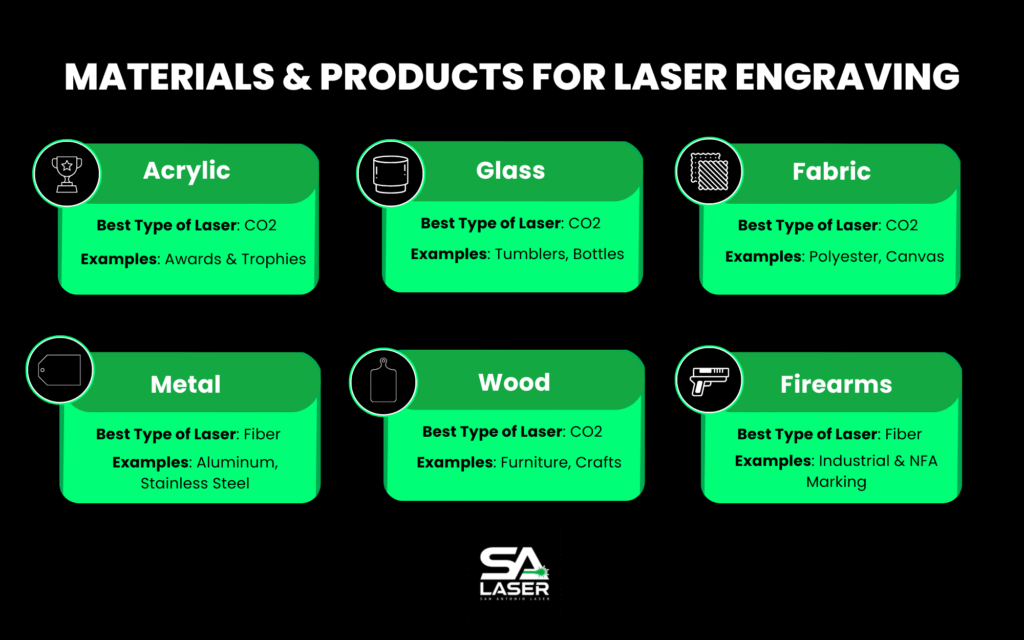

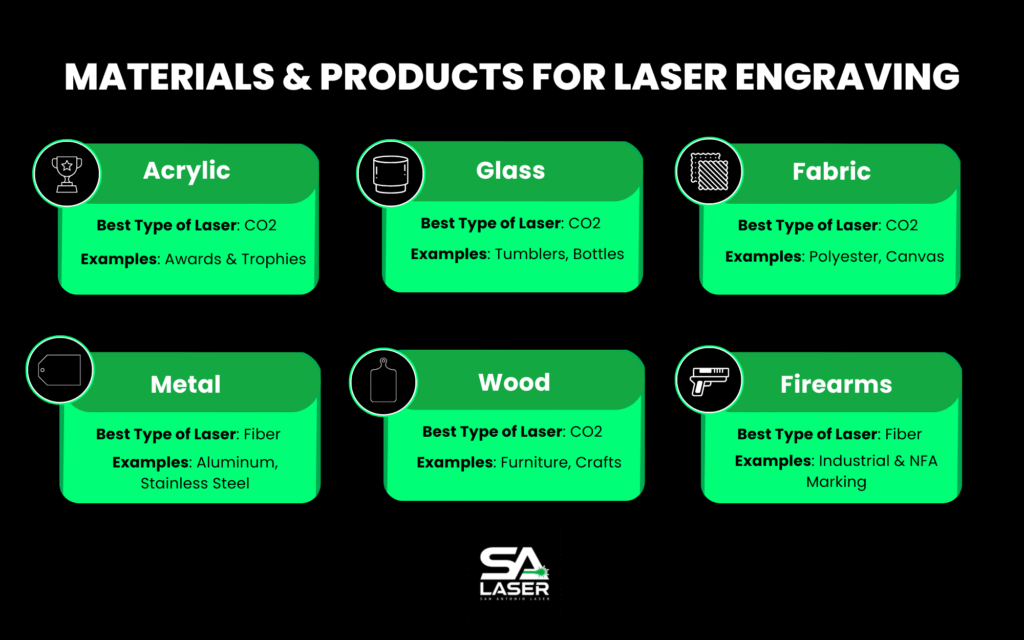

Starting a new laser engraving business or adding engraving capabilities to existing services opens up numerous opportunities across growing markets. The versatility of modern laser engraving machines allows entrepreneurs to work with diverse materials, including glass, acrylic, wood, and metals, to create personalized products and provide professional marking services. This flexibility means you can adapt your business model to match market demands and your expertise.

Best Type of Laser: CO2 Laser

Examples: Awards & Trophies, Keychains

Acrylic engraving produces elegant items with a frosted finish that customers love.

Wood engraving creates beautiful cutting boards and decorative items with rich, detailed designs.

Best Type of Laser: CO2 Laser

Examples: Tumblers, Plaques, Bottles

Glass engraving transforms ordinary items into personalized treasures.

Best Type of Laser: Fiber Laser

Examples: Titanium, Aluminum, Gold & Silver, Stainless Steel, Brass

Metal engraving offers personalized customization and marking to durable tags, tools, and more.

Best Type of Laser: CO2 Laser

Examples: Canvas, Linen

Fabric engraving adds custom designs to certain fabrics and clothing with high precision.

Best Type of Laser: CO2 Laser

Examples: Wallets, Journals, Keychains

Leader engraving adds sophistication to items like wallets, journals, and keychains.

Best Type of Laser: CO2 Laser

Examples: Furniture, Cutting Boards, Crafts

Wood engraving adds intricate designs to a variety of types of wood.

Best Type of Laser: Fiber Laser

Examples: Industrial Part Marking, NFA Engraving

Firearm engraving provides custom marking and stippling services.

Successful laser engraving businesses typically offer at least one of the following service types:

The most profitable specialties in laser-engraved items focus on:

Each specialty area requires understanding specific techniques and market demands, but mastering these services creates reliable revenue streams for your laser business.

Starting a laser engraving business begins with choosing between two main types of laser engravers. CO2 lasers work well with organic materials like wood, acrylic, and certain fabrics, while fiber lasers specialize in metal marking and engraving. Your choice should align with your target market and materials you plan to work with. When selecting your first machine, focus on these features:

For new business owners, budget planning should account for $15,000-30,000 for a professional-grade laser engraver. This investment includes the machine, necessary accessories, and initial training.

Starting your laser engraving business requires several foundational steps. First, register your business and obtain necessary local permits. Most areas require a business license and may need additional permits for operating equipment. Your workspace needs:

Create a basic business plan outlining your services, target market, and pricing structure. Research your local market to identify opportunities in areas like awards, promotional items, or industrial marking. Proper training is fundamental to success.

A comprehensive training program should cover:

Consider offering both finished products and engraving services to maximize revenue streams. This dual approach lets you create your own product line while also providing custom engraving services to other businesses and individuals.

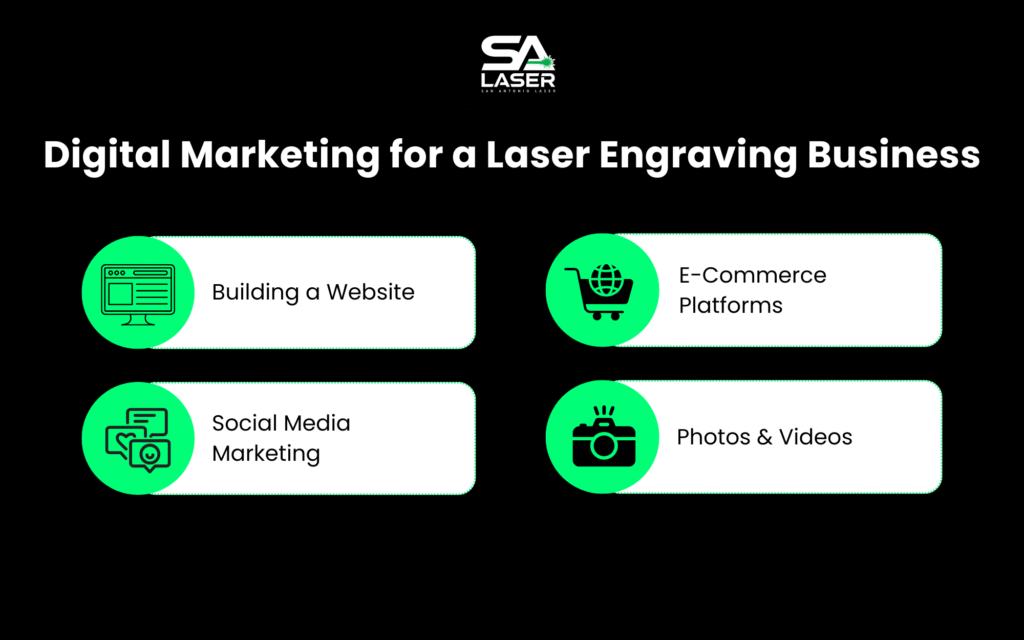

A strong digital presence is the foundation of any modern business, and marketing is particularly effective for laser companies since the service creates eye-catching products. Grow your online presence by:

Start with a professional portfolio website that showcases your best work across various materials and industries. Include high-quality photos of finished products, detailed descriptions of your services, and clear contact information.

Instagram and Pinterest are ideal social media platforms for sharing visually appealing photos of laser-engraved products and videos of your engraving process. Regular posts showing custom work, behind-the-scenes content, and customer testimonials help build trust with potential clients.

Selling or promoting through a platform like Facebook Marketplace or an Etsy shop helps you reach customers who are specifically searching for customized products. These online marketplaces provide built-in audiences and straightforward shipping solutions for small businesses.

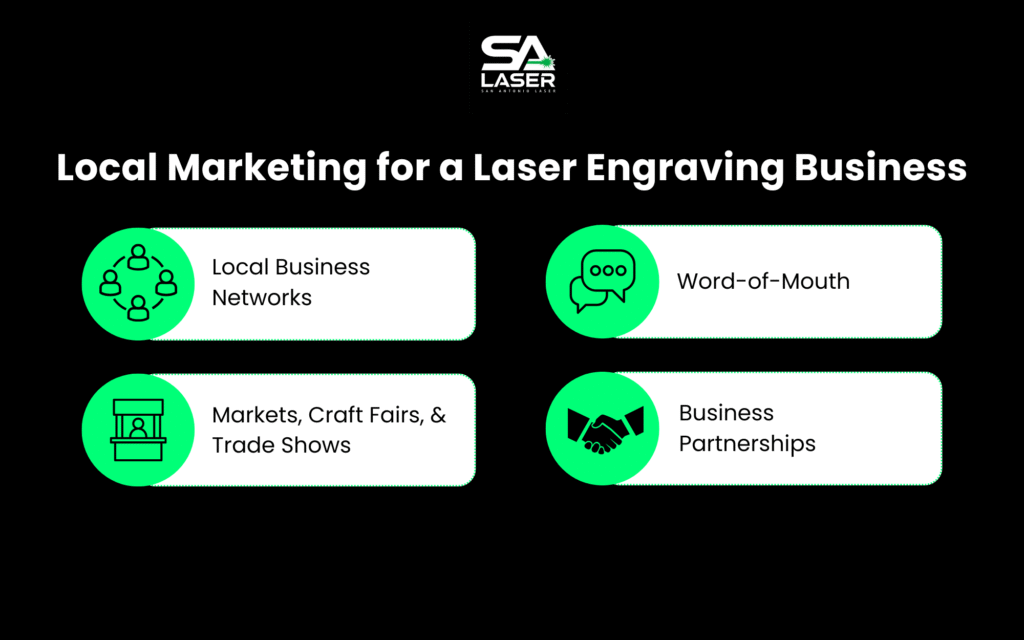

Building strong local connections drives sustained business growth. Ways to accomplish this in your local business community include:

Partner with complementary businesses like trophy shops, wedding planners, or corporate gift suppliers who can refer clients needing laser engraving services. These partnerships create win-win relationships that benefit both businesses.

Participate in craft fairs, trade shows, and maker markets where you can demonstrate your laser engraving capabilities live. These events let potential customers see the quality of your work firsthand and discuss custom projects face-to-face.

Join local business organizations and chambers of commerce to connect with other entrepreneurs and potential commercial clients. These organizations often host networking events where you can build relationships with business owners who need regular engraving services.

Utilizing one of the most effective marketing tools starts with delivering outstanding quality and customer service on every project. Happy customers naturally share their experiences with friends and colleagues, bringing in new business through trusted referrals.

Starting a laser engraving business opens up profitable opportunities across multiple markets and materials. Success in this field comes from choosing quality equipment, mastering the technology, and delivering consistent results to customers. The laser engraving industry continues to grow as more businesses and consumers seek personalized products and professional marking solutions.

SA Laser brings over a decade of hands-on experience to help you succeed. As a veteran-owned company that started as engravers themselves, they understand exactly what business owners need. Their high-quality laser machines come with everything required for immediate operation – from ventilation systems to brand-name laptops. SA Laser also provides Spark™ Laser Training and ongoing support to help you master your machine.

Ready to take the next step with laser cutting and engraving? Explore SA Laser’s fiber lasers, CO2 lasers, and their Business Starter Bundles that include the equipment, professional training, and technical support you need to serve a growing market.

Laser engraving is one of the fastest-growing industries in 2025, and starting a laser engraving business has never been more accessible. With the right machine, marketing, and product ideas, you can build a profitable business creating custom engraved gifts, personalized wood products, acrylic signage, and metal engravings. Whether you’re looking to go full time or start part time, this guide will walk you through everything you need to know.

Laser engraving is one of the most flexible and profitable small business opportunities today. Engravers can customize wood, acrylic, glass, stone, leather, metals, and even firearms depending on the machine you choose.

Personalized gear, products and keepsakes are always in demand, and with the versatility of CO2 and fiber laser engravers, you can easily fill that market and grow your business. The low material cost, combined with the ability to sell high-margin custom work, makes laser engraving a smart way to build a profitable side hustle or even a full-time career.

These benefits give you the tools and freedom to launch your laser engraving business confidently. By choosing the right products and approach, you can create a business that works for you.

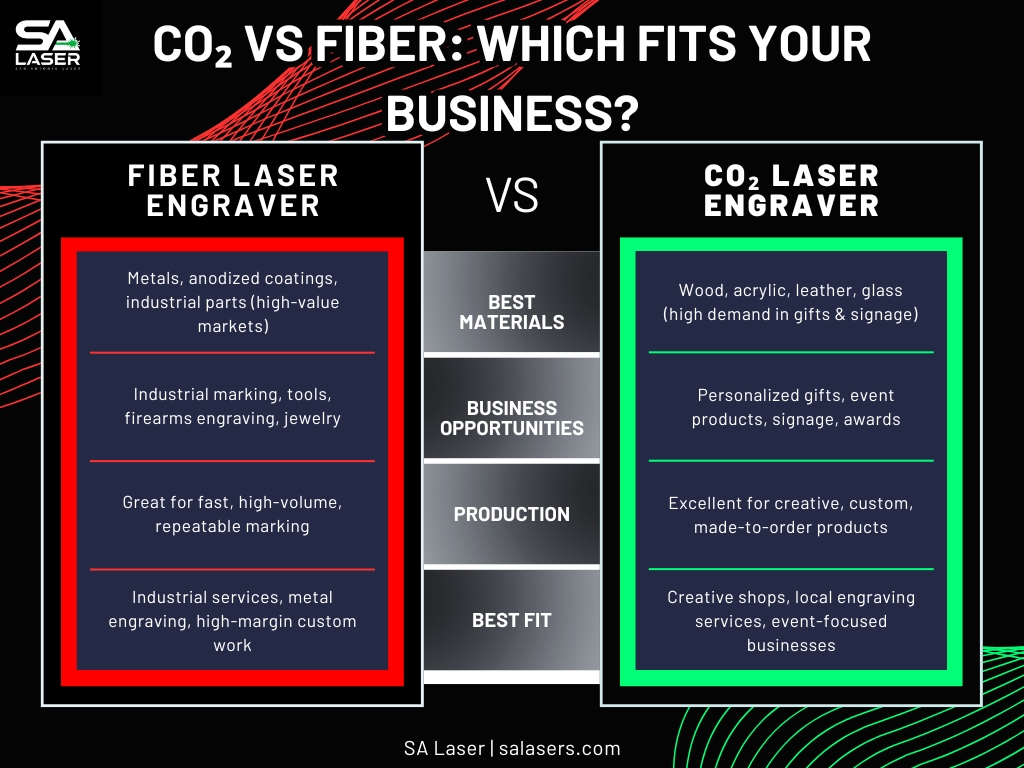

The machine you choose is the foundation of your laser engraving business. CO2 and fiber lasers are the two main options, each with unique strengths that fit different business types.

Your choice of machine defines your capabilities. Here’s a quick breakdown:

CO₂ lasers create a focused beam of light that easily engraves and cuts softer, organic materials. They’re the most popular entry point for small businesses thanks to their flexibility and affordability.

Fiber lasers use advanced fiber-optic technology to produce a highly precise beam, making them ideal for engraving metals and certain plastics. They’re widely used in industrial and high-detail applications where durability and speed matter most.

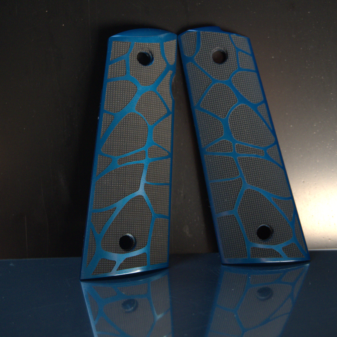

*Fiber lasers also are great for gun shop owners because they deliver crisp, permanent marks on slides, receivers, barrels, and other metal parts. They handle fine logos, serial numbers, deep contrast engraving, and repeatable batch marking with excellent speed and edge definition. With rotary fixtures and the right lenses, fiber systems make high-quality cylindrical work fast and consistent — which is why many gun shop owners choose fiber laser systems to expand services and boost revenue.

Many successful laser engraving businesses combine CO2 and fiber laser systems to maximize versatility and income streams. This hybrid approach allows you to serve both creative and industrial markets.

For example, a hybrid setup allows a business to address multiple market needs seamlessly:

The hybrid approach offers a powerful advantage: it gives a business full material capability, an expanded client base, and the flexibility to handle diverse orders. While it requires more workspace and a larger equipment investment, the payoff is significant — opening opportunities to serve a wider range of industries and boosting revenue potential. Effective workflow management is key to making the most of both systems and ensuring smooth operation.

Machine choice is only part of the journey; long-term success comes from smart business planning. Here are key areas every new engraver should consider:

Startup Costs & Budgeting: Plan for your laser machine, ventilation, software, raw materials, and any necessary shop setup. Entry-level CO₂ lasers may start under $10K, while fiber systems can run higher. Budgeting upfront prevents surprises.

Software & Design Tools: Most shops use design software like LightBurn for CO₂ machines and specialized programs for fiber marking. Strong design skills translate directly into higher-value products.

Legal & Licensing Basics: Depending on your state, you may need a business license, sales tax permit, or even an FFL (Federal Firearms License) if you’re engraving firearms. Handle compliance early to avoid setbacks.

Marketing & Customer Acquisition: Build your brand presence through social media, local networking, and an e-commerce site. Show off your projects online to attract both consumer and business clients.

Scaling & Growth Paths: Start small with gifts and signage, then expand into industrial contracts, corporate branding, or firearm engraving. Over time, you may add a second machine, hire staff, or specialize in high-demand niches.

With careful planning, the right tools, and a clear strategy, you’ll be ready to launch and grow your laser engraving business. These steps lay the groundwork for turning your vision into a sustainable and profitable venture.

Before you buy your first machine or begin promoting your shop, it helps to ask yourself a few key questions. These are the same things that experienced engravers consider when building a strong business plan.

Are you drawn to personalized gifts, promotional items for businesses, industrial engraving, or home decor? Knowing your product focus will help you choose the right machine, materials, and marketing approach.

Check platforms like Etsy, Amazon, and local engraving shops. See what’s popular and where there might be a gap you can fill. Market research helps you avoid overcrowded niches and find opportunities.

Your time commitment shapes your investment. A full-time laser engraving business may require a higher-powered machine with faster production, while a part-time shop can start with a smaller setup and scale later.

CO2 lasers: engrave wood, acrylic, leather, plastic, and glass. Perfect for signs, gifts, and home decor.

Fiber lasers: engrave metals like stainless steel, brass, and aluminum. Ideal for firearms, jewelry, tools, and industrial parts.

Some businesses start with one and eventually add the other for maximum versatility.

Different projects require different levels of detail. High-end jewelry engraving needs extreme precision, while large signs or decor may not. Choosing the right precision level will help you avoid overspending on features you don’t need.

If you plan to engrave serialized firearm parts, you’ll need an FFL. You can still run a successful business engraving non-serialized accessories, custom grips, or decorative parts without one.

Decide whether you’ll focus on online sales, local services, or both. Options include:

Online store or marketplace (Shopify, Etsy, Amazon Handmade)

Local engraving services for businesses, schools, and events

Direct-to-consumer products promoted through social media

A strong Instagram, TikTok, LinkedIn, or Facebook presence can showcase your work and attract customers. If you don’t have one yet, start building accounts now to share your designs and process.

Laser engraving machines are an investment. Many business owners take advantage of financing plans to get started sooner without heavy upfront costs. Looking for an easier way to start? SA Laser financing can help you take the first step.

Answering these questions gives you a clear roadmap for launching a successful laser engraving business in 2025.

Launching a laser engraving business in 2025 is more attainable than ever — but success comes from preparation. By answering the right questions, choosing the correct laser type, and building a clear business plan, you can avoid costly mistakes and accelerate your path to profitability. Whether your goal is a full-time engraving shop or a side hustle for extra income, CO₂ and fiber laser technology open doors to exciting creative and industrial markets. The key is to invest wisely, train thoroughly, and approach your business with intention.

Ready to launch your engraving business? Fill out the form to access your checklist and start building your plan with confidence. This guide will help you avoid common pitfalls, focus your efforts, and create a strong foundation for success. With SA Laser’s support, you’ll be able to move confidently from idea to income and build a business that lasts.

Many people enter the laser engraving world with excitement and high expectations. They invest in a machine, watch a few videos, maybe even complete a project or two. But somewhere along the way, the learning curve becomes overwhelming, business plans get stalled, and the machine that once symbolized freedom and creativity ends up sitting idle.

If that sounds familiar, you’re not alone. And more importantly — you’re not out of options.

The SA Laser Pathfinders Program is designed specifically for laser owners who already have equipment but never received the training, guidance, or structure to turn it into what they initially envisioned. Whether your machine has been gathering dust for months or you’ve been struggling to get consistent results, this program gives you a practical path forward.

Owning a laser should feel like a starting point, not a dead end. Everything we’ve included in the Pathfinders Program is there to help you make real progress, not just learn in theory. When people have a clear system and consistent guidance, they follow through. Projects get completed, orders start coming in, and that original spark turns into something steady.

It doesn’t matter how long your machine has been unused — what matters is your willingness to try again with the right guidance.

The truth is, most laser machine purchases don’t come with enough support. You may have received basic setup instructions or generic tutorials, but making the most out of your laser engraver takes more than just plugging in a machine.

“I’m not confident using LightBurn.”

“I thought I’d be selling products by now, but I haven’t made any progress.”

“I have the tools, but no clear idea where to start.”

“I’m overwhelmed by branding, marketing, and customer outreach.”

“I feel like I wasted money on something I’m not even using.”

These are exactly the kinds of challenges and gaps the Pathfinders Program is built to close, providing the training, support, and guidance you need to move past obstacles and start making real progress with your laser business.

When most people buy a laser machine, they picture what’s possible — engraving custom gifts, selling personalized products online, offering branded pieces for local businesses, or building something they can be proud of.

Maybe you had those same ideas. Maybe you saw potential in wedding signs, tumblers, memorials, awards, or home decor. You might’ve even had a name picked out or a logo saved on your phone.

The ideas were there. What was missing was the structure to follow through.

The Pathfinders Program helps take those early ideas and turn them into something real. With guidance, training, and a business framework built around your goals, you can finally start creating the work you imagined when you first started.

You don’t need to abandon your original vision. All you need is the right tools to bring it to life.

Sometimes it’s hard to picture what your machine can actually do. These examples are all made with a CO₂ laser and show the kinds of products people are regularly selling online. The pricing ranges on the backs of these images are based on real listings from marketplaces like Etsy and small business shops.

While CO₂ lasers are great for wood, acrylic, and coated materials, fiber lasers open the door to engraving on metals. From custom jewelry to serialized tools and firearm markings, fiber machines are used for high-precision work that holds real value. Below are just a few examples of fiber laser products and the price ranges they typically sell for.

At SA Laser, we’ve worked with hundreds of small business owners and hobbyists who all had one thing in common: they needed more than just a machine. They needed a partner who understood not just the technical side of laser engraving, but the reality of starting and growing a business from scratch.

That’s exactly why we built the Pathfinders Program — to offer real-world support, clear training, and a community that helps you move forward with confidence. Whether you’re picking things back up after a long break or finally ready to take your machine seriously, we’re here to guide you every step of the way.

If you’re tired of second-guessing your investment or wondering what could’ve been, this is your chance to take control of your journey and finally build something you believe in. Join the Pathfinders Program today.

The Short Answer: Fiber laser technology excels at marking metals, polymers, and some plastics, while CO2 lasers are best for organic materials like wood and acrylic. The best choice for you depends on your primary business applications and the different materials you’ll be engraving.

Choosing between a fiber laser machine and a CO2 laser is one of the most important decisions for business owners entering the laser engraving industry. These two laser technologies excel with specific materials and are best used for different purposes. While fiber lasers use a focused laser beam to mark metals and other hard surfaces with precision, CO2 lasers work through a gas-based system that’s perfect for non-metallic materials like wood and acrylic.

Understanding the distinct advantages of each laser type and which materials work best with each technology will help you select the right laser machine for your specific needs. Whether you’re starting a new engraving business or expanding your current services, we will help you make an informed decision that aligns with your goals.

Fiber laser technology uses specially designed optical fiber that delivers the laser beam through an optic cable. The beam operates at a wavelength that falls in the infrared spectrum. This shorter wavelength creates an extremely precise, concentrated beam that allows the laser to produce detailed designs on thin materials and complex shapes. Fiber lasers typically operate at power levels ranging from 20 to 100 watts for laser marking applications, providing exceptional control over the engraving process.

CO2 lasers generate their beam using a mixture of carbon dioxide, nitrogen, and helium gases housed in a sealed tube. When electricity runs through the gas-filled tube, it excites the CO2 molecules, causing them to release photons of light that bounce between mirrors to create the laser beam. These laser machines produce a beam with a wavelength about ten times longer than fiber laser wavelengths. This longer wavelength interacts differently with different materials, especially thicker materials like wood and acrylic. The beam delivery system of CO2 lasers uses a series of mirrors and a focusing lens to direct the laser to the work surface, allowing for precise control of engraving depth and detail.

Fiber lasers excel at working with metals and certain hard plastics. These machines create permanent, high-contrast marks on materials like stainless steel, aluminum, and copper. The focused beam produces precise engravings ideal for industrial applications such as serial numbers, barcodes, and product identification.

Small businesses in manufacturing and industrial sectors often use fiber lasers for:

CO2 lasers work exceptionally well with organic materials. These versatile laser engravers can process:

CO2 lasers are commonly used for lasers for:

Both laser types serve different business needs, with fiber lasers focusing on metal applications and CO2 lasers handling a broader range of organic and synthetic materials.

Power consumption tends to favor fiber lasers, which typically use less electricity than CO2 systems. This improved efficiency comes from their solid-state design that requires less cooling and produces less waste heat during operation. However, the upfront cost of a laser should be weighed against long-term benefits. Operating costs for both fiber and CO2 lasers often depend on operator efficiency and the business model rather than maintenance and power consumption. Some of these usage factors include:

When calculating return on investment, consider your primary application. Businesses focusing on metal engraving often recover the higher initial cost of fiber lasers through increased productivity and lower operating expenses. Companies working primarily with wood, acrylic, and other organic materials may find better value in CO2 systems despite higher operational costs.

The choice between fiber and CO2 technology should align with your business model, production volume, and material focus. Both systems can provide excellent returns when matched appropriately to their intended use.

The journey to selecting the perfect laser engraving machine for your business comes down to understanding your specific needs and material requirements. Your choice between fiber and CO2 laser technology will shape your business’s capabilities and determine the range of services you can offer your customers.

When investing in a laser engraving machine, consider factors like the materials you’ll work with most frequently, your workspace setup, and your budget. Look for machines that include complete systems with proper ventilation, cooling systems, and user-friendly controls. At SA Laser, we offer both fiber and CO2 laser machines and our hands-on Spark™ Laser Training program that turns beginners into confident operators.

Ready to take your business to the next level with professional laser cutting and engraving? Explore SA Laser’s selection of American-made fiber and CO2 laser machines. Our expert team will help match you with the perfect machine for your business needs and equip you with the knowledge you need to find success in engraving.

The Short Answer: Starting a laser engraving business requires careful planning. Success comes from choosing the right equipment, learning proper techniques, and identifying profitable market opportunities in your specific industry.

The laser engraving industry offers exciting opportunities for entrepreneurs and small business owners looking to start a successful business or add laser engraving services to their existing operation. This laser technology allows you to personalize and mark different materials, including acrylic, glass, wood, metal, and more. The target market spans multiple sectors, from creating custom awards and trophies to producing specialized industrial markings.

Small businesses across various industries can benefit from laser cutting and engraving capabilities. The versatility of laser engraving makes it an attractive standalone laser business or a smart add-on service that can boost revenue for existing operations.

Starting a profitable business in the laser engraving industry requires careful planning across several areas. Before purchasing the right equipment, you’ll want to develop a clear understanding of your target market and business requirements.

The first step is identifying your target customers. Focus on businesses and individuals who regularly need laser-engraved products like awards, signage, promotional products, and custom gifts. If you’re interested in providing services to other businesses, research local businesses that might benefit from laser engraving, including retailers, offices, schools, and event planners. Look for gaps in the market where you can offer unique products.

Study your local competition by visiting their websites, reviewing their services, and analyzing their pricing. Note which different materials they work with and what types of products they offer. This research helps you identify opportunities to differentiate your laser business and set competitive prices that reflect market rates while maintaining healthy profit margins.

Your business structure affects taxes and legal liability. Most small business owners in laser engraving start as sole proprietorships or LLCs. Consult a local business advisor to choose the right structure for your situation.

A professional laser engraving machine can range anywhere from $15,000 to $50,000, including fume extraction systems and various accessories. In addition to the initial investment, entrepreneurs should plan for 6-12 months of operating expenses while building a customer base. They should also arrange for other financial factors, such as workspace rent, inventory, and advertising.

Choosing between CO2 and fiber laser engraving machines is one of your first major decisions. CO2 lasers work well with different materials like wood, acrylic, and fabric. They offer flexibility for most laser engraving business applications. Fiber lasers specialize in metal marking and are built for industrial-grade laser engraving tasks.

Galvo laser systems use high-speed mirrors to direct the laser beam, offering high speed and precision. Ideal for intricate marking or engraving these systems typically require a smaller work area.

Gantry setups rely on linear or servo motos to move the laser head. These versatile systems are typically not as fast as galvo systems, but they are versatile and can cut or engrave large pieces and thicker materials.

SA Laser offers both galvo and gantry systems to help engravers find the machine that best fits their needs.

When setting up your laser workspace, consider that most entry-level laser engravers need at least a 4′ x 6′ area. Larger commercial laser machines may need 8′ x 10′ or more. Factor in space for material storage and finished product handling. Your power requirements will also vary, since standard CO2 lasers usually run on 110V while industrial fiber lasers may need 220V power.

A proper ventilation system removes fumes and particles produced during laser engraving. Look for engraving machines that include-

Running a successful laser business demands more than technical knowledge. You must develop accurate project pricing strategies that account for material costs, laser machine time, and design work. These skills extend into operations, safety, and other aspects of laser engraving.

Workplace safety is a top priority in the laser engraving industry. To prioritize safety, your workspace needs-

Operating a laser engraving business requires mastering specific technical abilities. At SA Laser, we offer Spark™ Laser Training, a thorough 5-day hands-on training program that covers laser engraving machine operation fundamentals, including proper setup, maintenance, and troubleshooting. You will learn design software to create and modify artwork for laser-engraved products. Understanding different materials like acrylic, wood, glass, and metal is also important, as each requires specific laser power settings and handling techniques.

Adding laser engraving services can open up new revenue streams for your small business. Your existing customer relationships provide a ready target market for personalized products and services. With opportunities for growth in several industries, a laser machine is an attractive option for a range of businesses.

Many successful businesses integrate laser engraving by offering customization options for their current product lines. For example, businesses can add personalization services, branding, and serial number marking for purchased items. Your established business infrastructure offers advantages when adding laser technology: you already have a workspace, business systems, and most importantly, a customer base that trusts you. This foundation allows you to focus on learning the laser engraver and developing unique products rather than building everything from scratch.

At SA Laser, we offer comprehensive Business Starter Bundles that are designed for new businesses and existing businesses looking to grow their capabilities. These bundles are complete with our fiber and CO2 laser machines, accessories, Spark™ Laser Training sessions, and payment plans to make the process easy.

Thanks to its range of materials and capabilities, different business types have unique opportunities to establish a profitable laser engraving service.

By offering firearm marking services, including NFA engraving, serial number marking, and customized designs for firearms and accessories, gun store owners can establish a new stream of income. This specialized service adds value for existing customers while meeting the rising demand for professional marking solutions.

Art businesses can expand their creative offerings through laser-engraved tumblers, trophies, signage, and more. With a laser engraving machine, artists can create intricate designs on wood, acrylic, glass, and more materials, opening up new possibilities for custom artwork and commissioned pieces.

Clothing and textile stores can differentiate themselves by adding laser engraving services. This allows for personalized clothing items, custom patches, promotional products, and more items that set your store apart from standard retail outlets.

After making a business plan and arrangements for a laser machine, start mapping out how your laser engraving business will fit into your current system.

Designate specific times for engraving machine work and determine how to balance it with existing operations. Consider starting with simple projects that complement your current products or services.

Look at your available space and plan where to place your laser engraving machine. Many laser machines are compact enough to fit into existing workspaces without major reorganization. Factor in proper ventilation requirements and safety considerations.

Develop a marketing strategy to promote these new services to your current customers first. Use your existing communication channels, such as email lists, social media platforms, or in-store signage, to announce your expanded capabilities. Show examples of personalized versions of products they already buy from you to spark interest in these new services.

Starting a laser engraving business can open up profitable business opportunities across many markets, from personalized laser-engraved products to industrial marking. Success in the laser business comes from choosing the right equipment, building a solid business plan foundation, developing your technical skills, and maintaining ongoing support and access to resources. Your focus should be on mastering laser technology, understanding your target market, and delivering high-quality products that meet customer needs.

SA Laser brings over a decade of hands-on experience to help you succeed in the laser engraving industry. We offer top-quality laser engraving machines with all necessary components, plus a 5-day Spark™ Laser Training that turns beginners into skilled operators. As a veteran-owned company based in the United States, we understand exactly what small business owners need to thrive.

Ready to start your laser engraving journey? Explore SA Laser’s state-of-the-art fiber and CO2 laser engraving machines and industry-leading training program. Our experts will guide you through every step of launching your successful business, from engraving machine selection to mastering advanced engraving techniques.

If you’re looking to tap into the booming world of custom products, learning how to start a laser engraving business is a smart move. With the right approach, laser engraving can be a profitable venture, catering to a wide range of industries from personalized gifts to industrial marking. In this guide, we’ll walk you through every step of starting your own laser engraving business, from equipment choices to marketing strategies.

The laser engraving industry has experienced significant growth over the past few years, driven by the demand for personalized products and high-precision marking. Here are some compelling reasons to start a laser engraving business:

Before diving into any business, it’s essential to understand the market. Conduct thorough research on your local and online competition. Identify what products and services are in demand. Common niches include:

Defining a niche will help you focus your efforts, target the right audience, and establish your brand identity.

The heart of your laser engraving business is the laser engraver itself. There are several types of laser engravers, each with its advantages:

When choosing your equipment, consider factors such as your niche, the materials you plan to work with, and your budget. Don’t forget to account for additional tools, such as air filtration systems and software for designing your engravings.

Your workspace is crucial for productivity and safety. Whether you’re working from home or renting a space, ensure you have:

Organize your workspace to maximize efficiency. Create designated areas for design, production, packaging, and storage.

Before you start offering services, take the time to learn and perfect your craft. Many laser engravers come with their own software, but you might want to invest in professional design software like Adobe Illustrator, CorelDRAW, or AutoCAD. These programs offer more advanced features and can help you create intricate designs that stand out.

Experiment with different materials and techniques. Practice makes perfect, and the more skilled you become, the more satisfied your customers will be.

Your brand is more than just a logo or a name—it’s the story and values that connect with your customers. Start by choosing a memorable business name, designing a professional logo, and creating a strong online presence.

A well-thought-out business plan is essential for guiding your growth. Include details like:

Your marketing strategy is key to attracting customers and growing your business. Here are some effective tactics to consider:

The quality of your work and the level of customer service you provide will determine your reputation in the market. Pay attention to detail, meet deadlines, and always strive to exceed customer expectations. Positive reviews and word-of-mouth referrals can be your most powerful marketing tools.

Once you’ve established a steady stream of customers, consider scaling your business. This could involve investing in more advanced equipment, expanding your product line, or hiring additional staff. Keep an eye on industry trends and continuously innovate to stay ahead of the competition.

Starting a laser engraving business isn’t without its challenges. Here are some common obstacles and how to overcome them:

Starting a laser engraving business can be a rewarding and profitable venture if you approach it with the right mindset and strategy. By investing in quality equipment, mastering your craft, and building a strong brand, you’ll be well on your way to success. Remember, the key to thriving in this industry is continuous learning, innovation, and customer satisfaction.

Ready to start your laser engraving business? Follow the steps in this guide, and you’ll be equipped with the knowledge and tools to carve out your niche in this exciting industry.