Laser engraving has become one of the most versatile, reliable, and cost-effective tools for small businesses looking to expand product offerings, strengthen branding, and provide customized services. Whether you run a retail shop, online store, engraving service, or promotional products business, adding a laser system can open doors to new revenue streams, streamline production, and help you stand out in competitive markets. Here are five practical ways laser engraving can help your small business grow and succeed.

Personalized products continue to be a top-selling category across retail, e-commerce, and gift markets. Laser engraving allows small businesses to create a wide variety of custom items—everything from engraved tumblers, cutting boards, and drinkware to signs, coasters, keychains, awards, and plaques. Even small touches, like adding a customer’s name or a special date, make products feel personal and memorable.

Personalized items encourage repeat purchases and referrals because customers are more likely to share something unique with friends and family. For example, a small business selling engraved wooden cutting boards for weddings or anniversaries can see consistent demand year-round. Adding customization options doesn’t have to be complicated either—modern laser systems can handle everything from one-off orders to bulk runs efficiently, making personalization accessible for businesses of any size.

Your branding goes beyond a logo or a website—it’s the overall experience customers have with your business. Laser engraving makes it simple to produce high-quality signage, nameplates, display pieces, branded merchandise, and point-of-sale displays that reinforce your professionalism. Engraved signs for your storefront, office, or trade show booth can make a huge difference in how your business is perceived. Materials like wood, acrylic, metal, and leather offer endless possibilities for customization. You could create sleek engraved desk signs for corporate clients, rustic wooden menus for a café, or professional awards for local businesses. Each engraved item is durable and visually appealing, creating a polished impression that builds trust.

Flexibility is one of the strongest advantages of laser engraving. A modern laser system can handle both one-off custom orders and larger batch production with ease. This opens opportunities for businesses to accept personalized or niche orders without dramatically increasing labor costs.

For instance, a small business offering engraved promotional items can quickly switch between products and designs, from custom keychains for a local event to engraved awards for corporate clients. The precision of a laser system ensures that every product is consistent and high-quality, even when producing large quantities. This allows small businesses to expand their offerings, enter new markets, and test product ideas with minimal financial risk. The ability to efficiently handle custom orders can set your business apart, creating a reputation for reliability and quality that customers will trust.

Community events, craft fairs, trade shows, and promotional events are excellent opportunities to connect with potential customers. Laser engraved products naturally stand out in these environments because of their quality and uniqueness. Items like custom ornaments, branded keychains, badges, plaques, and giveaway products can attract attention and create a professional, memorable presence.

For example, a small business selling engraved drinkware at a local craft fair can offer on-the-spot personalization, giving customers an experience that feels interactive and special. Engraved products also act as long-lasting promotional tools, reminding customers of your brand long after the event. By investing in distinctive, high-quality products for events, small businesses can maximize exposure and create meaningful connections with potential buyers.

Laser engraving offers unmatched versatility, allowing small businesses to work with a broad range of materials—including wood, acrylic, coated metals, leather, glass, and select plastics. This versatility makes it easy to introduce new products or test market demand without significant upfront costs. From home décor and personalized accessories to corporate gifts, awards, and custom signage, a single laser system can support dozens of product categories.

Small businesses can experiment with different materials, designs, and product types while minimizing waste and production errors. For example, a business could start with small, personalized items like engraved coasters and gradually expand into larger, more complex products such as wooden signage or metal awards. This flexibility allows businesses to grow strategically, diversify their offerings, and increase revenue without large investments in new equipment or manufacturing processes.

Adding laser engraving to your business workflow opens the door to new products, stronger branding, and expanded customization capabilities. With its precision, versatility, and ability to handle both simple and complex designs, laser engraving provides small businesses with a reliable way to upgrade services, increase efficiency, and generate additional revenue. For business owners ready to take the next step, SA Laser offers comprehensive online training and resources to guide you step-by-step, ensuring you can implement laser engraving successfully and confidently.

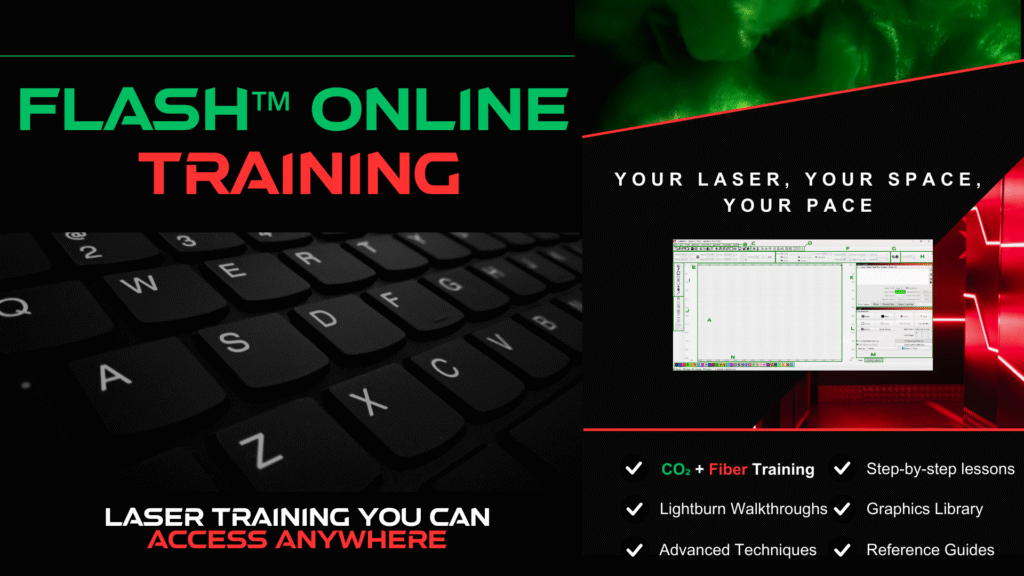

Mastering laser engraving has never been easier. With SA Laser’s online learning platform and Flash Fiber and CO2 laser training, you can gain real skills at your own pace, from the comfort of your own home. The platform provides structured instruction, hands-on exercises, and expert guidance designed to help you succeed, all while connecting with a community of fellow laser enthusiasts who share tips, projects, and encouragement.

Online learning gives you flexibility and efficiency that traditional classes cannot match. Lessons are broken into short, easy-to-follow videos, so you can absorb the material without feeling overwhelmed. You can revisit any lesson as often as needed and immediately apply new techniques on your own laser system.

If you’re looking for a place to learn laser engraving while connecting with other engravers, our online learning platform was built exactly for you. It gives you a space to explore new techniques, improve your engraving skills, and understand your machine with clarity. You get the benefit of guided learning while still working from home, and the added support of other learners who share your passion. This combination makes the entire learning process feel natural, organized, and approachable for anyone ready to grow.

Every course is taught by instructors with real experience in CO2 and Fiber laser systems. You learn practical skills that make an immediate difference in the quality of your engraving. Lessons walk you through settings, techniques, troubleshooting, and project setup in a way that feels organized and intentional. Students often mention how quickly they gain confidence because the instruction is clear, direct, and rooted in real engraving workflows. This level of detail is especially valuable for beginners who want reliable laser engraving guidance instead of guessing which settings to use.

These courses are built to help you avoid mistakes, understand why certain results happen, and work smarter with your machine. You get to learn in a way that supports your schedule and progress. With consistent explanations, visual demonstrations, and real life examples, you develop a deeper understanding of how CO2 and Fiber lasers behave on different materials. This helps you improve your technique, solve problems faster, and create cleaner, more professional engravings.

On our LaserHeads platform, you’ll find full CO2 laser courses, Fiber laser courses, and complete LightBurn training. Everything is broken down into modules that guide you from foundational skills to more advanced engraving techniques. You can learn LightBurn layout tools, material testing, engraving presets, file preparation, and settings optimization in a way that makes sense even if you have never used design software before.

The combination of expert guidance, hands on practice, and a connected learning environment helps you build skills that lead to consistent, professional results. You’ll learn settings, materials, layout, focus, project organization, and complete engraving workflows you can use right away. The courses are structured to teach you how to develop repeatable results, improve your engraving clarity, and understand why each adjustment matters. Over time, these methods help reduce material waste, cut down your trial and error process, and increase your overall confidence with your laser system.

If you want something more immersive, SA Laser offers a five day in person Spark™ training experience at our facility in San Antonio, Texas. This course gives you direct feedback, live demonstrations, and guided practice time that helps you grow faster. It covers machine setup, material handling, engraving techniques, software skills, and workflow strategy in a way that accelerates your confidence and your results. The in person experience allows you to work closely with instructors, see how different techniques behave in real time, and ask questions as they come up.

Your success is the heart of every course. These lessons are designed to help you apply new techniques quickly, understand your machine fully, and learn without feeling overwhelmed. You get the benefit of expert instruction, structured learning, and the support of a community that celebrates your progress with you. It creates a learning environment that feels encouraging, productive, and genuinely enjoyable. Each course is made to help beginners build confidence and give experienced users a clearer understanding of advanced engraving techniques, all with practical examples you can use right away.

These courses help you elevate your craft, grow your business, improve your workflow, and feel confident in every project you start. With a mixture of video training, hands on materials, LightBurn instruction, and community support, you build the kind of long term knowledge that improves both creativity and production quality.

Experience the convenience, clarity, and community of SA Laser’s online learning platform. Explore the courses, watch previews, and start learning at your own pace with support that stays with you. You get a full library of laser engraving education designed to help you improve step by step and grow steadily.

Launching a laser engraving business can feel out of reach if you’re worried about upfront costs. The truth is, you can get started without a large initial investment. Through SA Laser’s trusted financing partners, Clicklease and Geneva Capital, you can launch your engraving business with no money down and flexible payment options that fit your goals.

Geneva Capital offers a standout financing opportunity: no payments for three months, affordable fixed payments, and potential tax benefits under Section 179, all with quick approvals. This makes it easier than ever to invest in professional-grade CO₂ or fiber laser systems without straining your budget.

Geneva Capital has introduced a special term promotion exclusively for SA Laser clients. Catering to a range of credit situations from Good to Excellent. Those with top-tier credit can especially benefit as they're entitled to make ZERO payments for the initial 3 months.

One of the biggest hurdles when starting a laser business is equipment cost. That’s why SA Laser partners with Geneva Capital and Clicklease to make financing accessible and straightforward. Both offer quick approvals and affordable monthly payments designed for new entrepreneurs.

Clicklease works with a wide range of budgets and credit profiles, while Geneva Capital’s no-money-down program gives you three months payment-free to produce, sell, and build revenue before your first bill is due.

If you’re starting from scratch, our Business Starter Bundles are also a great solution. They combine a laser system, essential accessories, and training in one easy-to-finance package—helping you launch your business with confidence and minimal upfront costs.

Geneva Capital has introduced a special term promotion exclusively for SA Laser clients. Catering to a range of credit situations from Good to Excellent. Those with top-tier credit can especially benefit as they're entitled to make ZERO payments for the initial 3 months.

Clicklease offers fast approvals and affordable payment plans designed for small business owners. Just fill out the financing application, which takes less than five minutes and gets you one step closer to launching your business.

When you finance through Clicklease or Geneva Capital, you can invest in the right machine without waiting months to save. Both partners offer flexible payment options that make it possible to start now and grow at your own pace.

CO₂ lasers are perfect for creative entrepreneurs who want to work with wood, acrylic, leather, glass, and certain plastics. They’re ideal for personalized products like signage, décor, and promotional gifts. With affordable monthly payments, you can start producing right away instead of delaying your plans.

Fiber lasers are built for high-precision metal engraving. They’re great for industrial marking, personalized tools, and firearm components. Financing lets you enter these profitable markets without the heavy upfront cost that stops many small businesses.

With SA Laser’s financing partners, you can start with the machine that fits your current goals and add another system later as your business expands.

Before investing in software or paid courses, take advantage of free resources to sharpen your skills. Trial versions of design programs like LightBurn allow you to explore workflows before purchasing a license. You can also find free online templates, video tutorials, and guides that help you practice engraving techniques and project setups.

Learning from community creators, YouTube educators, and design forums can give you valuable insights while keeping expenses low.

After your laser is up and running, it’s time to get your work noticed. With no money down financing, you can put more of your budget into marketing instead of large upfront costs.

Start small by showcasing your designs on Instagram, TikTok, or Pinterest. Post process videos, before-and-after shots, and finished projects to attract new customers. You can also network locally by collaborating with small businesses or offering custom samples for events.

Financing through Clicklease or Geneva Capital gives you financial breathing room to invest where it matters most — growing your audience and building momentum.

Starting with no money down means you can take manageable steps without financial pressure. Begin with simple, high-margin products such as engraved tumblers, signs, or keychains to build your reputation and generate revenue quickly.

As you grow, reinvest your profits into upgrades or additional laser systems. Both Clicklease and Geneva Capital offer flexible options for scaling when you’re ready to expand.

Geneva Capital’s current opportunity makes it even easier to get started. You’ll pay nothing upfront, make no payments for the first three months, and benefit from fixed monthly costs and fast approvals. It’s an affordable way to focus on production, marketing, and building your brand before your first payment is due.

When you partner with SA Laser, you’re not just buying a machine. You’re gaining access to financing, training, and community support that set you up for long-term success.

Starting a laser engraving business doesn’t have to be expensive or intimidating. With SA Laser, Geneva Capital, and Clicklease, you can begin building your dream business with no money down, no stress, and full confidence in your growth potential.

Geneva Capital has introduced a special term promotion exclusively for SA Laser clients. Catering to a range of credit situations from Good to Excellent. Those with top-tier credit can especially benefit as they're entitled to make ZERO payments for the initial 3 months.

Clicklease offers fast approvals and affordable payment plans designed for small business owners. Just fill out the financing application, which takes less than five minutes and gets you one step closer to launching your business.

The Short Answer: Laser engraving guns allows for precise, permanent customization of firearms through detailed designs, text, and patterns. Professional fiber laser machines can engrave various gun materials safely while maintaining firearm integrity.

Customizing a gun serves multiple purposes beyond aesthetics. Personalized engraving adds unique identification markers, creates brand recognition for gun shops, and allows for specialized marking required by law enforcement and military organizations. Modern laser engraving technology has revolutionized this process, offering firearm businesses a precise, reliable method for adding permanent markings to various gun materials.

Fiber laser and CO2 laser technology offer different capabilities when it comes to firearm engraving. Fiber lasers work by producing a concentrated beam of light that interacts directly with metal surfaces. This makes them perfect for marking and engraving firearms, as they can create precise, permanent marks on metal surfaces without damaging the material structure.

CO2 lasers, while excellent for materials like wood and acrylic, aren’t typically the best choice for gun engraving. Their wavelength doesn’t interact well with metals, making them unsuitable for most firearm applications. Professional gun customization shops typically use fiber laser systems because they produce clean, sharp marks that won’t compromise the firearm.

Most modern firearms are manufactured using various metals. Fiber laser engraving works effectively on all these materials, though the process settings may vary for each:

Surface preparation plays an important role in achieving superior quality. The area to be engraved should be clean and free from oils, debris, or protective coatings. While extensive surface preparation isn’t typically needed for fiber laser engraving, some manufacturers recommend light cleaning before the marking process.

The marking depth for firearms must be carefully controlled. If it’s too shallow, the mark may wear away over time. If it’s too deep, it could affect the internal components and structural integrity of the firearm. Professional-grade fiber lasers allow precise control over marking depth, making them a popular option for firearms.

Laser engraving ensures crisp, permanent markings that won’t fade over time, maintaining both the firearm’s aesthetic appeal and compliance with identification requirements. Custom logos and artwork allow for truly unique personalization. Common locations include the slide, frame, or barrel.

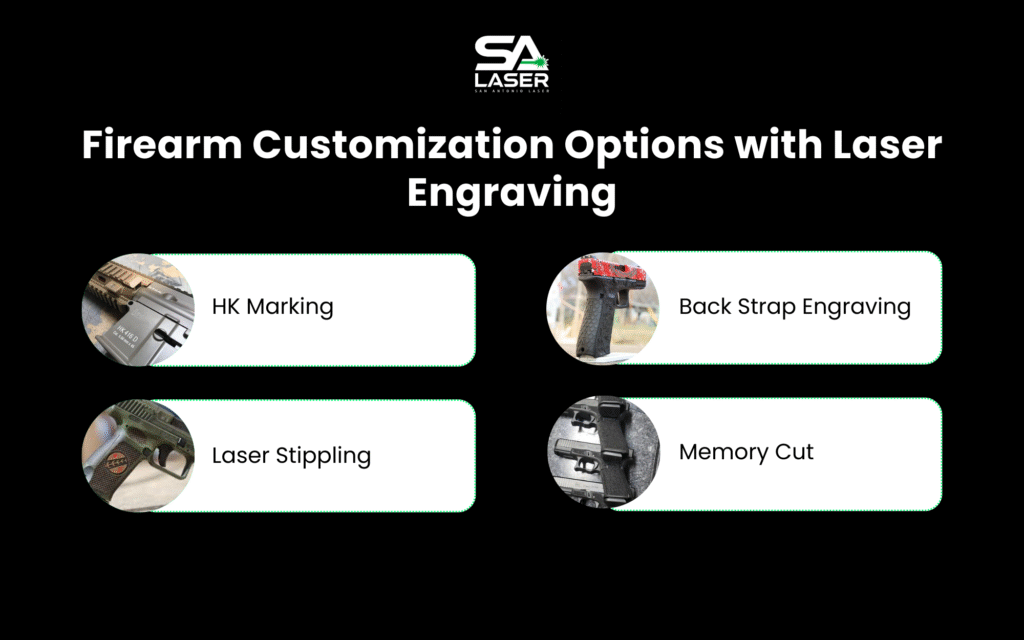

Modern laser systems can reproduce company logos, military insignias, custom artwork, and more detailed images on metal surfaces. Laser engraving offers firearm owners multiple ways to personalize their guns with precision and style. The most common engraving options include:

HK marking is a method used to replicate the authentic factory-style markings found on Heckler & Koch (HK) firearms. These markings can include model designations, manufacturer information, proof marks, and serial numbers. High-precision laser engraving technology allows for HK markings applied with exact depth, font, and placement to match original specifications. This process is ideal for restorations, clone builds, or enhancing the authenticity of custom rifle, pistol, or shotgun projects.

Text and serial numbers remain the standard choice for practical identification. Professional engravers can add serial numbers, names, contact information, or meaningful quotes in various fonts and sizes.

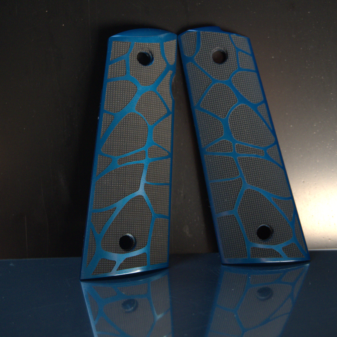

Back strap engraving transforms the rear portion of a firearm’s grip into a canvas for personalization. These tactical-style embellishments not only elevate the firearm’s visual appeal but can also provide subtle texturing for improved grip and handling. Popular choices include scrollwork, geometric patterns, and tactical-style embellishments that complement the gun’s aesthetic while maintaining a professional appearance.

Laser stippling uses precision laser engraving to create textured patterns on firearm frames, improving both grip and aesthetics. Unlike traditional hand stippling, laser stippling produces consistent, repeatable designs with exact depth control, allowing for intricate patterns, logos, or custom artwork. Handgun and Glock stippling not only provides a more secure, slip-resistant surface but also offers a professional-quality finish and endless design possibilities for personalization.

A memory cut refers to the second part of a notorious “double undercut” modification on modern polymer-frame firearms. This precise cut, which is not allowed in many competition shooting events, provides a reference point for the support hand and knuckle. Using laser cutting for a memory cut ensures exact placement, clean edges, and a professional finish without compromising the firearm’s structural integrity.

Metal etching uses laser engraving techniques to create detailed markings, patterns, and designs on a gun’s metal surfaces. Etching can range from deep engravings to lighter surface markings, depending on the desired effect. By offering a durable, corrosion-resistant finish that stands up to regular handling and use, the method is a popular choice for custom guns.

When planning your firearm engraving project, several technical factors affect the final result:

Licensed manufacturers and dealers must maintain detailed records of all laser-engraved firearms, including the original serial numbers and any additional markings added. The records should document the date of engraving, the specific modifications made, and the identity of both the firearm owner and the person performing the work.

When laser engraving firearms, federal regulations set strict guidelines that must be followed. The Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) requires all serial numbers and identifying marks to be permanently engraved to a minimum depth of .003 inches. These markings must include the manufacturer’s name, model, caliber, and serial number on the frame or receiver.

Proper machine operation starts with practicing safety and efficiency before beginning an engraving project:

When handling firearms for engraving, follow these guidelines throughout the process:

Having proper procedures in place for both routine operation and emergency situations will help protect operators and maintain consistent engraving quality.

Incorporating laser engraving services in your business requires professional-grade equipment and expert support. As a veteran-owned company with over a decade of experience, SA Laser delivers both. Our heavy-duty fiber laser machines effectively meet many different needs for laser engraving success.

SA Laser is the only laser manufacturing company with a Federal Firearms License (FFL) and a Special Occupational Taxpayer (SOT) designation. We’ve set ourselves apart with our Edge Series and our industry-leading Spark™ Training Program, offering all the support you need to master firearm engraving techniques like stippling and NFA markings.

Beyond equipment, SA Laser provides specialized services for firearms, including precise NFA engravings and laser stippling. Our expertise comes from years of hands-on experience as engravers. With over 800 successful laser engravers as clients, SA Laser has built a reputation for excellence in several industries.

Ready to update your engraving capabilities with firearms customization? Explore our laser engraving machines, industry-leading Spark™ Laser Training, and must-have laser accessories.

Laser engraving is one of the fastest-growing industries in 2025, and starting a laser engraving business has never been more accessible. With the right machine, marketing, and product ideas, you can build a profitable business creating custom engraved gifts, personalized wood products, acrylic signage, and metal engravings. Whether you’re looking to go full time or start part time, this guide will walk you through everything you need to know.

Laser engraving is one of the most flexible and profitable small business opportunities today. Engravers can customize wood, acrylic, glass, stone, leather, metals, and even firearms depending on the machine you choose.

Personalized gear, products and keepsakes are always in demand, and with the versatility of CO2 and fiber laser engravers, you can easily fill that market and grow your business. The low material cost, combined with the ability to sell high-margin custom work, makes laser engraving a smart way to build a profitable side hustle or even a full-time career.

These benefits give you the tools and freedom to launch your laser engraving business confidently. By choosing the right products and approach, you can create a business that works for you.

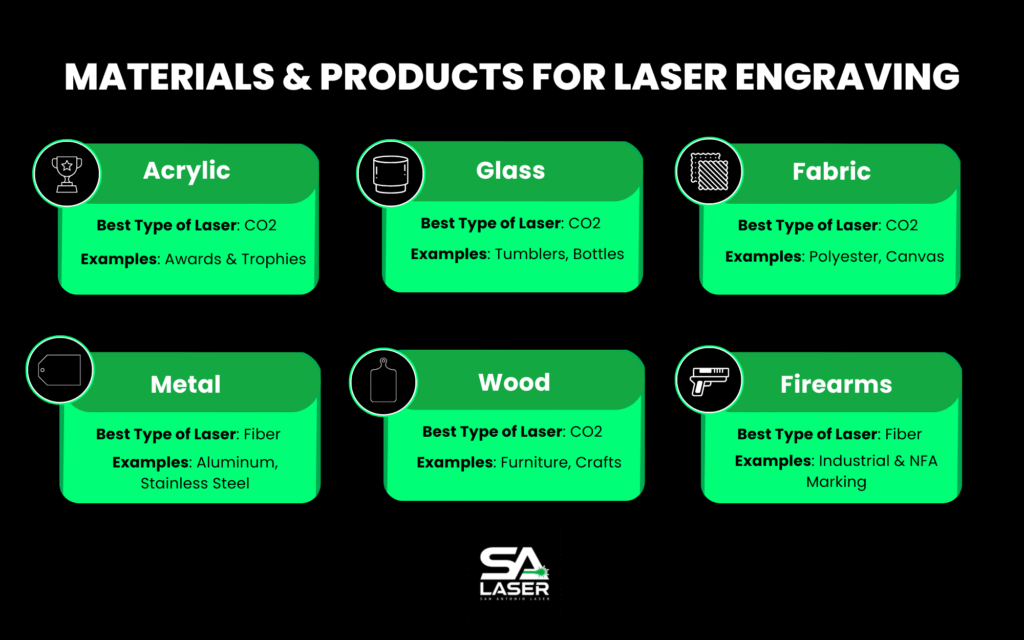

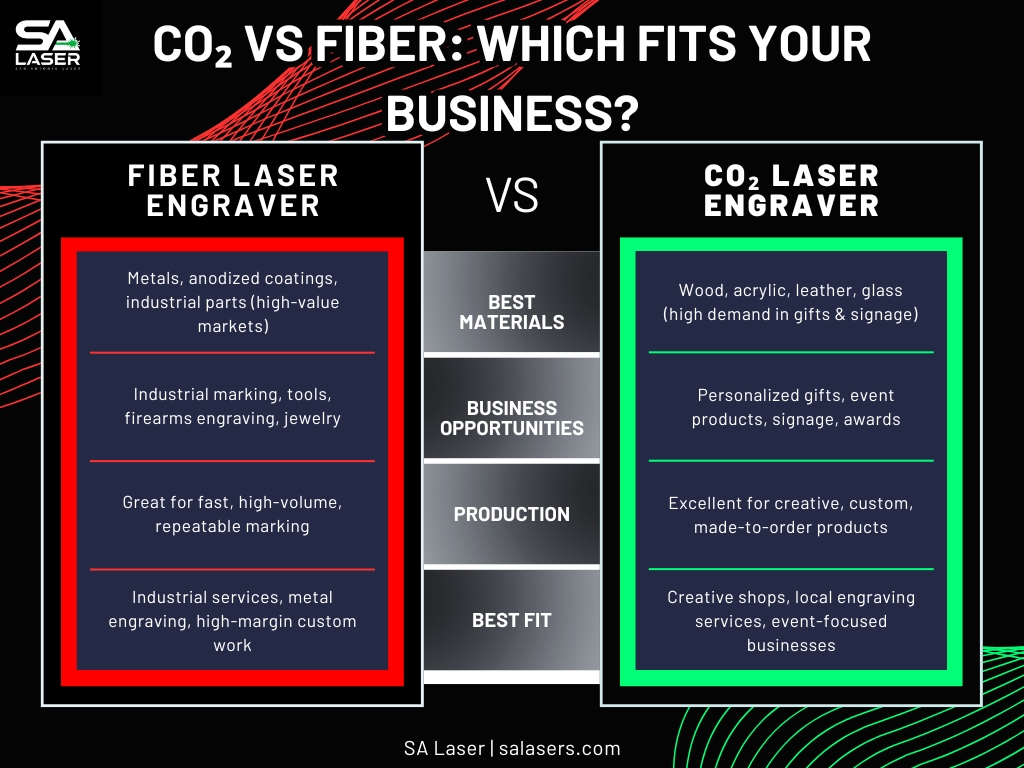

The machine you choose is the foundation of your laser engraving business. CO2 and fiber lasers are the two main options, each with unique strengths that fit different business types.

Your choice of machine defines your capabilities. Here’s a quick breakdown:

CO₂ lasers create a focused beam of light that easily engraves and cuts softer, organic materials. They’re the most popular entry point for small businesses thanks to their flexibility and affordability.

Fiber lasers use advanced fiber-optic technology to produce a highly precise beam, making them ideal for engraving metals and certain plastics. They’re widely used in industrial and high-detail applications where durability and speed matter most.

*Fiber lasers also are great for gun shop owners because they deliver crisp, permanent marks on slides, receivers, barrels, and other metal parts. They handle fine logos, serial numbers, deep contrast engraving, and repeatable batch marking with excellent speed and edge definition. With rotary fixtures and the right lenses, fiber systems make high-quality cylindrical work fast and consistent — which is why many gun shop owners choose fiber laser systems to expand services and boost revenue.

Many successful laser engraving businesses combine CO2 and fiber laser systems to maximize versatility and income streams. This hybrid approach allows you to serve both creative and industrial markets.

For example, a hybrid setup allows a business to address multiple market needs seamlessly:

The hybrid approach offers a powerful advantage: it gives a business full material capability, an expanded client base, and the flexibility to handle diverse orders. While it requires more workspace and a larger equipment investment, the payoff is significant — opening opportunities to serve a wider range of industries and boosting revenue potential. Effective workflow management is key to making the most of both systems and ensuring smooth operation.

Machine choice is only part of the journey; long-term success comes from smart business planning. Here are key areas every new engraver should consider:

Startup Costs & Budgeting: Plan for your laser machine, ventilation, software, raw materials, and any necessary shop setup. Entry-level CO₂ lasers may start under $10K, while fiber systems can run higher. Budgeting upfront prevents surprises.

Software & Design Tools: Most shops use design software like LightBurn for CO₂ machines and specialized programs for fiber marking. Strong design skills translate directly into higher-value products.

Legal & Licensing Basics: Depending on your state, you may need a business license, sales tax permit, or even an FFL (Federal Firearms License) if you’re engraving firearms. Handle compliance early to avoid setbacks.

Marketing & Customer Acquisition: Build your brand presence through social media, local networking, and an e-commerce site. Show off your projects online to attract both consumer and business clients.

Scaling & Growth Paths: Start small with gifts and signage, then expand into industrial contracts, corporate branding, or firearm engraving. Over time, you may add a second machine, hire staff, or specialize in high-demand niches.

With careful planning, the right tools, and a clear strategy, you’ll be ready to launch and grow your laser engraving business. These steps lay the groundwork for turning your vision into a sustainable and profitable venture.

Before you buy your first machine or begin promoting your shop, it helps to ask yourself a few key questions. These are the same things that experienced engravers consider when building a strong business plan.

Are you drawn to personalized gifts, promotional items for businesses, industrial engraving, or home decor? Knowing your product focus will help you choose the right machine, materials, and marketing approach.

Check platforms like Etsy, Amazon, and local engraving shops. See what’s popular and where there might be a gap you can fill. Market research helps you avoid overcrowded niches and find opportunities.

Your time commitment shapes your investment. A full-time laser engraving business may require a higher-powered machine with faster production, while a part-time shop can start with a smaller setup and scale later.

CO2 lasers: engrave wood, acrylic, leather, plastic, and glass. Perfect for signs, gifts, and home decor.

Fiber lasers: engrave metals like stainless steel, brass, and aluminum. Ideal for firearms, jewelry, tools, and industrial parts.

Some businesses start with one and eventually add the other for maximum versatility.

Different projects require different levels of detail. High-end jewelry engraving needs extreme precision, while large signs or decor may not. Choosing the right precision level will help you avoid overspending on features you don’t need.

If you plan to engrave serialized firearm parts, you’ll need an FFL. You can still run a successful business engraving non-serialized accessories, custom grips, or decorative parts without one.

Decide whether you’ll focus on online sales, local services, or both. Options include:

Online store or marketplace (Shopify, Etsy, Amazon Handmade)

Local engraving services for businesses, schools, and events

Direct-to-consumer products promoted through social media

A strong Instagram, TikTok, LinkedIn, or Facebook presence can showcase your work and attract customers. If you don’t have one yet, start building accounts now to share your designs and process.

Laser engraving machines are an investment. Many business owners take advantage of financing plans to get started sooner without heavy upfront costs. Looking for an easier way to start? SA Laser financing can help you take the first step.

Answering these questions gives you a clear roadmap for launching a successful laser engraving business in 2025.

Launching a laser engraving business in 2025 is more attainable than ever — but success comes from preparation. By answering the right questions, choosing the correct laser type, and building a clear business plan, you can avoid costly mistakes and accelerate your path to profitability. Whether your goal is a full-time engraving shop or a side hustle for extra income, CO₂ and fiber laser technology open doors to exciting creative and industrial markets. The key is to invest wisely, train thoroughly, and approach your business with intention.

Ready to launch your engraving business? Fill out the form to access your checklist and start building your plan with confidence. This guide will help you avoid common pitfalls, focus your efforts, and create a strong foundation for success. With SA Laser’s support, you’ll be able to move confidently from idea to income and build a business that lasts.

The Short Answer: Fiber laser technology excels at marking metals, polymers, and some plastics, while CO2 lasers are best for organic materials like wood and acrylic. The best choice for you depends on your primary business applications and the different materials you’ll be engraving.

Choosing between a fiber laser machine and a CO2 laser is one of the most important decisions for business owners entering the laser engraving industry. These two laser technologies excel with specific materials and are best used for different purposes. While fiber lasers use a focused laser beam to mark metals and other hard surfaces with precision, CO2 lasers work through a gas-based system that’s perfect for non-metallic materials like wood and acrylic.

Understanding the distinct advantages of each laser type and which materials work best with each technology will help you select the right laser machine for your specific needs. Whether you’re starting a new engraving business or expanding your current services, we will help you make an informed decision that aligns with your goals.

Fiber laser technology uses specially designed optical fiber that delivers the laser beam through an optic cable. The beam operates at a wavelength that falls in the infrared spectrum. This shorter wavelength creates an extremely precise, concentrated beam that allows the laser to produce detailed designs on thin materials and complex shapes. Fiber lasers typically operate at power levels ranging from 20 to 100 watts for laser marking applications, providing exceptional control over the engraving process.

CO2 lasers generate their beam using a mixture of carbon dioxide, nitrogen, and helium gases housed in a sealed tube. When electricity runs through the gas-filled tube, it excites the CO2 molecules, causing them to release photons of light that bounce between mirrors to create the laser beam. These laser machines produce a beam with a wavelength about ten times longer than fiber laser wavelengths. This longer wavelength interacts differently with different materials, especially thicker materials like wood and acrylic. The beam delivery system of CO2 lasers uses a series of mirrors and a focusing lens to direct the laser to the work surface, allowing for precise control of engraving depth and detail.

Fiber lasers excel at working with metals and certain hard plastics. These machines create permanent, high-contrast marks on materials like stainless steel, aluminum, and copper. The focused beam produces precise engravings ideal for industrial applications such as serial numbers, barcodes, and product identification.

Small businesses in manufacturing and industrial sectors often use fiber lasers for:

CO2 lasers work exceptionally well with organic materials. These versatile laser engravers can process:

CO2 lasers are commonly used for lasers for:

Both laser types serve different business needs, with fiber lasers focusing on metal applications and CO2 lasers handling a broader range of organic and synthetic materials.

Power consumption tends to favor fiber lasers, which typically use less electricity than CO2 systems. This improved efficiency comes from their solid-state design that requires less cooling and produces less waste heat during operation. However, the upfront cost of a laser should be weighed against long-term benefits. Operating costs for both fiber and CO2 lasers often depend on operator efficiency and the business model rather than maintenance and power consumption. Some of these usage factors include:

When calculating return on investment, consider your primary application. Businesses focusing on metal engraving often recover the higher initial cost of fiber lasers through increased productivity and lower operating expenses. Companies working primarily with wood, acrylic, and other organic materials may find better value in CO2 systems despite higher operational costs.

The choice between fiber and CO2 technology should align with your business model, production volume, and material focus. Both systems can provide excellent returns when matched appropriately to their intended use.

The journey to selecting the perfect laser engraving machine for your business comes down to understanding your specific needs and material requirements. Your choice between fiber and CO2 laser technology will shape your business’s capabilities and determine the range of services you can offer your customers.

When investing in a laser engraving machine, consider factors like the materials you’ll work with most frequently, your workspace setup, and your budget. Look for machines that include complete systems with proper ventilation, cooling systems, and user-friendly controls. At SA Laser, we offer both fiber and CO2 laser machines and our hands-on Spark™ Laser Training program that turns beginners into confident operators.

Ready to take your business to the next level with professional laser cutting and engraving? Explore SA Laser’s selection of American-made fiber and CO2 laser machines. Our expert team will help match you with the perfect machine for your business needs and equip you with the knowledge you need to find success in engraving.

Laser engraving is revolutionizing how small businesses, hobbyists, and creators customize products and add professional-quality detail. If you’re new to laser engraving and wondering how to choose the right laser engraving machine, this guide breaks down everything you need to know, from understanding laser types to selecting the best beginner laser engraver for your projects.

Laser engraving uses a focused laser beam to remove material from surfaces such as wood, acrylic, leather, glass, and metal, creating permanent marks, designs, and textures. Unlike traditional mechanical engraving, laser engraving is contactless, which means cleaner lines, finer details, and no tool wear. Most laser machines today offer both engraving and cutting capabilities, with adjustments in power and speed depending on your material and design.

Power: Look for a machine with adjustable power output. Beginners often benefit from 40 to 60 watts in CO₂ lasers to handle a wide variety of materials. Power affects how deep the laser cuts or engraves — too little won’t mark well, too much can damage delicate materials.

Speed: Speed controls how fast the laser head moves over your workpiece. Slower speeds increase engraving depth and detail but take longer. A machine with flexible speed settings lets you fine-tune for each material and design complexity.

Resolution (DPI): Resolution impacts engraving detail, especially in photos and shaded images. Higher DPI means sharper, finer engraving but slower processing times. For basic text or logos, lower DPI is sufficient and faster.

For the best beginner laser engraver, CO₂ machines provide the greatest flexibility and ease of use. Fiber lasers serve professionals focused on metalwork and high-volume production.

Match your typical project size, small (12×8 in) for jewelry and small crafts, medium (24×18 in) for signs and trophies, or large (48×36 in+) for batch production and large-format cutting.

For beginners, a 40 to 60 watt CO₂ laser is ideal for cutting and engraving a wide range of materials. Fiber lasers usually range 20 to 50 watts for metal marking.

Choose machines compatible with popular laser software like LightBurn or RDWorks, which support vector and raster file formats (SVG, DXF, AI, JPG, PNG).

Look for interlocks, emergency stops, and exhaust ports or filtration systems to manage fumes safely.

Choose machines compatible with popular laser software like LightBurn or EZCAD2, which support vector and raster file formats such as SVG, DXF, AI, JPG, and PNG. At SA Laser, our SPARK Laser Training provides expert instruction on both fiber and co2 laser operation and software use, including detailed lessons on LightBurn. This course is designed to build your confidence and skillset from the ground up, helping you achieve great results with your laser machine.

Before you start engraving, your artwork needs to be properly prepared. Laser machines follow exact paths and tones in your design, so getting the setup right is key to clean, accurate results.

Vector files (like SVG or DXF) are made of lines and shapes, perfect for cutting and scoring. Use thin lines (0.001″ stroke) to signal cut lines, and color-code layers — for example, red for cutting and blue for engraving.

Raster files (like JPG or PNG) are best for photos or detailed shading. Convert your image to grayscale, adjust contrast, and apply a dithering method like Jarvis or Floyd–Steinberg to get smoother tones.

Use alignment boxes or marks to position your artwork accurately on irregular items like tumblers or wood slabs.

Reverse engraving (where the background is engraved and the design is left untouched) can make text or logos stand out on darker materials.

For detailed raster engraving, stick to 250–300 DPI for clear image reproduction.

Always match your file’s dimensions to your machine’s bed size to avoid off-center jobs.

LightBurn is a great program for managing both vector and raster layers. It lets you assign different power and speed settings to each color-coded section for full control over your design.

Regular cleaning of lenses and mirrors with isopropyl alcohol ensures consistent beam quality. Lubricate machine rails and bearings every 20 to 30 hours of use. Always ventilate fumes outdoors or use filtration systems, and never leave a running laser unattended.

At SA Laser, we provide not just machines but a complete solution including expert training, comprehensive support, and community resources. Our turnkey laser systems come with two-year warranties, personalized Spark Training classes, and lifetime access to our online community where you can connect with top engravers nationwide.

Whether you’re buying your first laser engraver or scaling your business, SA Laser delivers quality machines, trusted expertise, and unmatched customer care.

When investing in a laser engraving machine, it’s easy to be dazzled by exciting features, projected speed, or even just a low price. But beneath the surface, the real value in a laser machine lies in the quality of the components hidden inside. In this post, we’re taking you behind the scenes of your laser machine to understand what parts matter most, and why choosing reliable components is essential to protecting your investment.

Buying a laser isn’t just about the upfront cost. It’s a long-term investment, and you deserve the confidence that comes with knowing your machine is both reliable and built to last. Unfortunately, not all machines are of the same quality. Some manufacturers cut corners by using refurbished parts, knock-offs, or whatever happens to be lying around in their warehouse. This can lead to performance issues, cause damage to important components, and even shorten the lifespan of your laser machine. Let’s take a closer look at what’s inside a fiber laser system and why quality matters at every step.

Controller Cards: Manufacturers like JCZ make around 16,000 cards a year, yet over 45,000 fiber lasers are sold annually claiming to use JCZ. That math doesn’t add up. Many are knock-offs.

Laser Sources: Easily branded and sold as premium, even when they’re subpar or refurbished.

Power Supplies: Poor-quality units frequently fail within months—an issue we see reported often in user forums.

Lenses: Cheaply made lenses can cause ghosting or back reflection, ruining detailed work.

Small Parts: Components like switches and emergency stops may seem minor, but when they fail, they can stop production—or worse, compromise safety.

Without these critical checks, even machines with name-brand parts can fail when it matters most. Before you buy, always ask about the supplier’s quality control process; it’s one of the most important factors protecting your investment.

With SA Laser, you can trust that quality has been built in from the start.

A reputable laser supplier will perform multiple rounds of hardware and software testing before shipment. This includes: 1) load testing all power supplies under maximum current, 2) ensuring the firmware matches the controller card, 3) aligning the laser source with the galvo head to prevent beam distortion, and 4) verifying that all external safety switches function properly.

Machines without these checks are more likely to fail, even if they technically have “name-brand” parts. Ask your supplier what kind of pre-shipping inspection they perform—it’s a vital part of the purchasing process.

When shopping for a laser engraving machine, it’s important to ask about more than just the specs. You should ask specific questions about the components and the quality control process. A high-quality laser system begins with the right questions:

What’s the difference between a fiber laser and a CO₂ laser engraver?

Are the controller cards from a verified supplier like JCZ? Are the lenses made by a reputable brand like Opex?

Is the power supply industrial-grade and reliable?

Are the emergency stop and key switch safety features OSHA-compliant?

What software is compatible — LightBurn, EZCAD, RDWorks?

Asking these key questions before buying your laser engraver can save you thousands in costly repairs and protect your professional reputation.

Founded in 2012 by laser professionals who understood exactly what features matter most, SA Laser has always been fueled by a passion for innovative excellence. As a veteran-owned business, discipline, integrity, and accountability are built into our DNA. We operate with a mission mindset: clear goals, high standards, and a relentless focus on service. When you partner with SA Laser, you’re backed by a team that shows up with purpose every single day. Rooted in service, driven by innovation, and focused on your success — that’s the SA Laser standard.

Unlike other manufacturers, SA Laser offers an incredible 5-day hands-on, in-person training program. From fiber and CO₂ laser calibration to advanced software proficiency, our Spark™ training ensures operators gain real confidence and mastery. Furthermore, our strong after-sales support puts a dedicated team behind you long after your purchase. Whether you’re growing your business or just getting started, we’re here to support you every step of the way.

We maintain a 3-to-1 student-to-teacher ratio to ensure every participant receives personal attention and hands-on guidance. The training covers everything from surface prep and machine operation to graphic design principles, marketing strategies, and engraving techniques for flat and cylindrical materials.

Beyond the classroom, you’ll have continued access to a supportive community and expert guidance. You’ll have access to refresher videos, a private customer forum, and responsive U.S.-based support whenever you need help. From setup to scaling your business, we’re here to make sure you succeed.

Our systems are engineered for those who need reliable, high-performance results. Every system comes fully equipped with essential features like ventilation, active cooling, and durable 3-axis motorized rotary options, which are typically reserved for more expensive models. We also offer a variety of advanced features to further enhance your system’s capabilities.

Our Edge Series fiber lasers delivers precision and reliability for engraving everything from tools and firearms to jewelry and business cards. It creates crisp, permanent marks on metals and select plastics, with multiple wattage options to suit your workflow.

The Razor Series is built for serious speed, offering 4X faster performance than traditional systems and making cutting and engraving simple whether you’re a beginner or a pro.

The Blade Light CO₂ laser is a compact solution for tight workspaces, ideal for smaller projects without sacrificing performance.

And with the Saber Laser Welder, you get a fast, efficient, and versatile machine that brings serious power to any shop.

With SA Laser, you get a fully-loaded, industrial-grade system that’s ready to perform right out of the box. We provide the tools, training, and support to ensure your success, no matter your business needs.

At SA Laser, we’re not just selling machines; we’re building lasting partnerships. From personalized consultations and expert advice to hands-on guidance throughout your journey, we’re committed to your growth. After the sale, we continue to support you with regular check-ins, refresher resources, and ongoing education, ensuring you’re equipped to excel. Our customers are at the heart of everything we do, and we’re proud to grow alongside you every step of the way.

At SA Laser, quality is a promise we make to our customers and honor for a lifetime. Our commitment to excellence begins the moment you trust us with your vision, and it continues for as long as you need us. Whether it’s about ensuring every machine leaves our facility in flawless condition or driving across state lines to support a customer in need, we’re dedicated to keeping our promise.

Quality isn’t just a benchmark—it’s a mindset that shapes our entire culture. That belief starts at the top with our CEO, Steven Ratliff, who’s long stood by the idea that excellence should be evident in every detail, every action, and every relationship.

Every product that leaves our facility is personally and carefully packaged to ensure it meets our high quality standards, and we uphold that standard throughout the entire shipping process. Excellence isn’t just about getting it right—it’s about how we respond when things go wrong.

When one of our clients in Ohio received a machine that had been damaged during transit, we didn’t just file a claim and wish them luck. Instead, we loaded a brand new unit into an enclosed trailer and hit the road ourselves. Two of our team members even stayed the weekend to assist with delayed engraving projects.

That level of service isn’t the exception at SA Laser—it’s the rule we govern ourselves by.

Our customers don’t just buy a product; they buy confidence. Confidence that their investment will perform flawlessly from day one. Confidence that our support won’t end after delivery. And confidence that they’re working with a company that actually cares. At SA Laser, we believe real partnerships are built on trust, accountability, and going the extra mile—literally. That’s why we treat every order like it’s our only one, and every customer like they’re part of the team.

If you’re looking for more than just a machine—if you want a partner who’s just as invested in your success as you are—then you’ve come to the right place. Let’s build something incredible together.

Laser engraving metal is a powerful way to add detail, precision, and durability to a wide range of products. From jewelry and firearms to industrial parts and custom gifts, engraving metal with a laser can produce high-quality results that stand out. In this guide, we’ll walk you through the steps of how to laser engrave metal effectively, using tips from the experts at SA Lasers.

Laser engraving is ideal for marking metal surfaces with intricate designs, logos, serial numbers, and text. It offers a precision unmatched by traditional engraving methods. Plus, laser engraving doesn’t involve direct contact with the material, so there’s no wear and tear on the machine or need for consumable parts.

There are two main types of lasers commonly used in metal engraving: Fiber lasers and CO2 lasers. Both types have their strengths, depending on the project.

Fiber Lasers: Fiber lasers are best suited for metal engraving as they produce a small, precise beam ideal for marking metals. They are effective on stainless steel, aluminum, brass, copper, and other metals. SA Lasers’ Polymetal 30-watt Fiber Laser is an excellent choice for high-precision metal engraving.

CO2 Lasers: CO2 lasers are more versatile but are generally not the first choice for metals unless the surface is coated. For engraving non-metal materials like wood or acrylic, SA Lasers’ Razor Series CO2 Laser performs exceptionally well.

Here’s a step-by-step guide to laser engraving metal:

Not all metals are the same. Consider the properties of the material you are working with. Fiber lasers, for example, perform exceptionally well on metals like stainless steel, aluminum, and brass, providing deep, clear engravings. Make sure your laser engraver is equipped to handle the specific metal.

For the best engraving results, ensure the metal surface is clean and free from any dust or oils. Use a soft cloth and a mild cleaner to remove impurities. This step is essential for achieving consistent and high-quality engravings.

Using your preferred design software, import your graphic or text. SA Lasers’ SPARK training curriculum guides clients on preparing designs for engraving, including vectorizing and adjusting for optimal clarity.

Finding the right settings for power, speed, and frequency is critical in laser engraving metal. These settings determine how deep and dark the engraving will be. Fiber lasers, like SA Lasers’ Polymetal 30-watt, often require lower speeds and higher power for deeper marks on harder metals.

Before starting your full engraving, do a test run on a scrap piece of metal. Proper focus ensures that the laser beam hits the metal at the right angle, achieving the sharpest possible engraving. Adjust the focal distance until you reach the desired clarity.

Once your settings are optimized, you’re ready to engrave. With your fiber laser in position, start the engraving process. Monitor the engraving to ensure consistent quality and depth.

Choose a Quality Machine: For professional results, use a reliable, high-precision machine like SA Lasers’ Polymetal 30-watt fiber laser, which is specifically designed for metal engraving.

Experiment with Depth: Different applications call for varying engraving depths. A lighter mark may be suitable for aesthetics, while a deeper engraving is necessary for industrial marking.

Consider Adding a Protective Coating: After engraving, you may want to add a clear protective coating to enhance durability, particularly if the engraved item will be exposed to the elements.

Follow Safety Protocols: Metal engraving generates fumes and particles. Ensure you are in a well-ventilated area and wear protective eyewear as needed.

Laser engraving on metal has applications across various industries:

SA Lasers is a leader in high-quality laser engravers and provides unparalleled support and training. Our fiber and CO2 lasers are built for precision, reliability, and durability, helping professionals achieve exceptional results. With our SPARK training curriculum, you’ll receive in-depth guidance on how to operate your laser and maximize its potential.

SA Lasers stands behind each machine with comprehensive support, ensuring that you can confidently tackle any engraving project.

Whether you’re a professional engraver or a business looking to enhance your product offerings, SA Lasers has the perfect machine and training for your needs. Visit salasers.com to explore our laser engraving solutions and learn more about how we can help you excel in laser engraving metal.

For more information, contact SA Lasers and take the first step toward mastering metal engraving today!