Laser engraving is one of the fastest-growing industries in 2025, and starting a laser engraving business has never been more accessible. With the right machine, marketing, and product ideas, you can build a profitable business creating custom engraved gifts, personalized wood products, acrylic signage, and metal engravings. Whether you’re looking to go full time or start part time, this guide will walk you through everything you need to know.

Laser engraving is one of the most flexible and profitable small business opportunities today. Engravers can customize wood, acrylic, glass, stone, leather, metals, and even firearms depending on the machine you choose.

Personalized gear, products and keepsakes are always in demand, and with the versatility of CO2 and fiber laser engravers, you can easily fill that market and grow your business. The low material cost, combined with the ability to sell high-margin custom work, makes laser engraving a smart way to build a profitable side hustle or even a full-time career.

These benefits give you the tools and freedom to launch your laser engraving business confidently. By choosing the right products and approach, you can create a business that works for you.

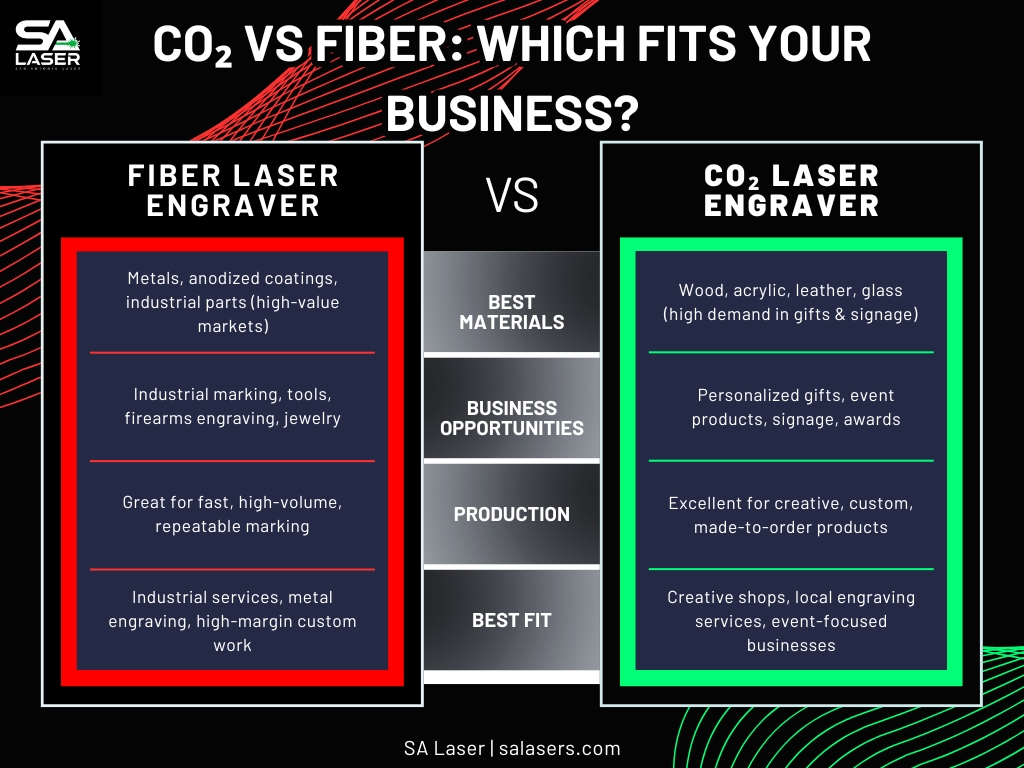

The machine you choose is the foundation of your laser engraving business. CO2 and fiber lasers are the two main options, each with unique strengths that fit different business types.

Your choice of machine defines your capabilities. Here’s a quick breakdown:

CO₂ lasers create a focused beam of light that easily engraves and cuts softer, organic materials. They’re the most popular entry point for small businesses thanks to their flexibility and affordability.

Fiber lasers use advanced fiber-optic technology to produce a highly precise beam, making them ideal for engraving metals and certain plastics. They’re widely used in industrial and high-detail applications where durability and speed matter most.

*Fiber lasers also are great for gun shop owners because they deliver crisp, permanent marks on slides, receivers, barrels, and other metal parts. They handle fine logos, serial numbers, deep contrast engraving, and repeatable batch marking with excellent speed and edge definition. With rotary fixtures and the right lenses, fiber systems make high-quality cylindrical work fast and consistent — which is why many gun shop owners choose fiber laser systems to expand services and boost revenue.

Many successful laser engraving businesses combine CO2 and fiber laser systems to maximize versatility and income streams. This hybrid approach allows you to serve both creative and industrial markets.

For example, a hybrid setup allows a business to address multiple market needs seamlessly:

The hybrid approach offers a powerful advantage: it gives a business full material capability, an expanded client base, and the flexibility to handle diverse orders. While it requires more workspace and a larger equipment investment, the payoff is significant — opening opportunities to serve a wider range of industries and boosting revenue potential. Effective workflow management is key to making the most of both systems and ensuring smooth operation.

Machine choice is only part of the journey; long-term success comes from smart business planning. Here are key areas every new engraver should consider:

Startup Costs & Budgeting: Plan for your laser machine, ventilation, software, raw materials, and any necessary shop setup. Entry-level CO₂ lasers may start under $10K, while fiber systems can run higher. Budgeting upfront prevents surprises.

Software & Design Tools: Most shops use design software like LightBurn for CO₂ machines and specialized programs for fiber marking. Strong design skills translate directly into higher-value products.

Legal & Licensing Basics: Depending on your state, you may need a business license, sales tax permit, or even an FFL (Federal Firearms License) if you’re engraving firearms. Handle compliance early to avoid setbacks.

Marketing & Customer Acquisition: Build your brand presence through social media, local networking, and an e-commerce site. Show off your projects online to attract both consumer and business clients.

Scaling & Growth Paths: Start small with gifts and signage, then expand into industrial contracts, corporate branding, or firearm engraving. Over time, you may add a second machine, hire staff, or specialize in high-demand niches.

With careful planning, the right tools, and a clear strategy, you’ll be ready to launch and grow your laser engraving business. These steps lay the groundwork for turning your vision into a sustainable and profitable venture.

Before you buy your first machine or begin promoting your shop, it helps to ask yourself a few key questions. These are the same things that experienced engravers consider when building a strong business plan.

Are you drawn to personalized gifts, promotional items for businesses, industrial engraving, or home decor? Knowing your product focus will help you choose the right machine, materials, and marketing approach.

Check platforms like Etsy, Amazon, and local engraving shops. See what’s popular and where there might be a gap you can fill. Market research helps you avoid overcrowded niches and find opportunities.

Your time commitment shapes your investment. A full-time laser engraving business may require a higher-powered machine with faster production, while a part-time shop can start with a smaller setup and scale later.

CO2 lasers: engrave wood, acrylic, leather, plastic, and glass. Perfect for signs, gifts, and home decor.

Fiber lasers: engrave metals like stainless steel, brass, and aluminum. Ideal for firearms, jewelry, tools, and industrial parts.

Some businesses start with one and eventually add the other for maximum versatility.

Different projects require different levels of detail. High-end jewelry engraving needs extreme precision, while large signs or decor may not. Choosing the right precision level will help you avoid overspending on features you don’t need.

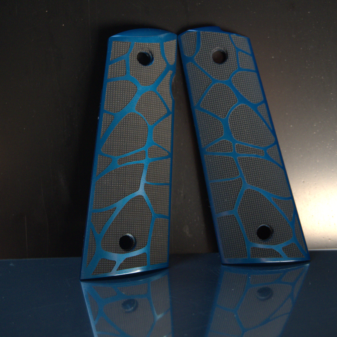

If you plan to engrave serialized firearm parts, you’ll need an FFL. You can still run a successful business engraving non-serialized accessories, custom grips, or decorative parts without one.

Decide whether you’ll focus on online sales, local services, or both. Options include:

Online store or marketplace (Shopify, Etsy, Amazon Handmade)

Local engraving services for businesses, schools, and events

Direct-to-consumer products promoted through social media

A strong Instagram, TikTok, LinkedIn, or Facebook presence can showcase your work and attract customers. If you don’t have one yet, start building accounts now to share your designs and process.

Laser engraving machines are an investment. Many business owners take advantage of financing plans to get started sooner without heavy upfront costs. Looking for an easier way to start? SA Laser financing can help you take the first step.

Answering these questions gives you a clear roadmap for launching a successful laser engraving business in 2025.

Launching a laser engraving business in 2025 is more attainable than ever — but success comes from preparation. By answering the right questions, choosing the correct laser type, and building a clear business plan, you can avoid costly mistakes and accelerate your path to profitability. Whether your goal is a full-time engraving shop or a side hustle for extra income, CO₂ and fiber laser technology open doors to exciting creative and industrial markets. The key is to invest wisely, train thoroughly, and approach your business with intention.

Ready to launch your engraving business? Fill out the form to access your checklist and start building your plan with confidence. This guide will help you avoid common pitfalls, focus your efforts, and create a strong foundation for success. With SA Laser’s support, you’ll be able to move confidently from idea to income and build a business that lasts.

At SA Laser, quality is a promise we make to our customers and honor for a lifetime. Our commitment to excellence begins the moment you trust us with your vision, and it continues for as long as you need us. Whether it’s about ensuring every machine leaves our facility in flawless condition or driving across state lines to support a customer in need, we’re dedicated to keeping our promise.

Quality isn’t just a benchmark—it’s a mindset that shapes our entire culture. That belief starts at the top with our CEO, Steven Ratliff, who’s long stood by the idea that excellence should be evident in every detail, every action, and every relationship.

Every product that leaves our facility is personally and carefully packaged to ensure it meets our high quality standards, and we uphold that standard throughout the entire shipping process. Excellence isn’t just about getting it right—it’s about how we respond when things go wrong.

When one of our clients in Ohio received a machine that had been damaged during transit, we didn’t just file a claim and wish them luck. Instead, we loaded a brand new unit into an enclosed trailer and hit the road ourselves. Two of our team members even stayed the weekend to assist with delayed engraving projects.

That level of service isn’t the exception at SA Laser—it’s the rule we govern ourselves by.

Our customers don’t just buy a product; they buy confidence. Confidence that their investment will perform flawlessly from day one. Confidence that our support won’t end after delivery. And confidence that they’re working with a company that actually cares. At SA Laser, we believe real partnerships are built on trust, accountability, and going the extra mile—literally. That’s why we treat every order like it’s our only one, and every customer like they’re part of the team.

If you’re looking for more than just a machine—if you want a partner who’s just as invested in your success as you are—then you’ve come to the right place. Let’s build something incredible together.

Laser engraving metal is a powerful way to add detail, precision, and durability to a wide range of products. From jewelry and firearms to industrial parts and custom gifts, engraving metal with a laser can produce high-quality results that stand out. In this guide, we’ll walk you through the steps of how to laser engrave metal effectively, using tips from the experts at SA Lasers.

Laser engraving is ideal for marking metal surfaces with intricate designs, logos, serial numbers, and text. It offers a precision unmatched by traditional engraving methods. Plus, laser engraving doesn’t involve direct contact with the material, so there’s no wear and tear on the machine or need for consumable parts.

There are two main types of lasers commonly used in metal engraving: Fiber lasers and CO2 lasers. Both types have their strengths, depending on the project.

Fiber Lasers: Fiber lasers are best suited for metal engraving as they produce a small, precise beam ideal for marking metals. They are effective on stainless steel, aluminum, brass, copper, and other metals. SA Lasers’ Polymetal 30-watt Fiber Laser is an excellent choice for high-precision metal engraving.

CO2 Lasers: CO2 lasers are more versatile but are generally not the first choice for metals unless the surface is coated. For engraving non-metal materials like wood or acrylic, SA Lasers’ Razor Series CO2 Laser performs exceptionally well.

Here’s a step-by-step guide to laser engraving metal:

Not all metals are the same. Consider the properties of the material you are working with. Fiber lasers, for example, perform exceptionally well on metals like stainless steel, aluminum, and brass, providing deep, clear engravings. Make sure your laser engraver is equipped to handle the specific metal.

For the best engraving results, ensure the metal surface is clean and free from any dust or oils. Use a soft cloth and a mild cleaner to remove impurities. This step is essential for achieving consistent and high-quality engravings.

Using your preferred design software, import your graphic or text. SA Lasers’ SPARK training curriculum guides clients on preparing designs for engraving, including vectorizing and adjusting for optimal clarity.

Finding the right settings for power, speed, and frequency is critical in laser engraving metal. These settings determine how deep and dark the engraving will be. Fiber lasers, like SA Lasers’ Polymetal 30-watt, often require lower speeds and higher power for deeper marks on harder metals.

Before starting your full engraving, do a test run on a scrap piece of metal. Proper focus ensures that the laser beam hits the metal at the right angle, achieving the sharpest possible engraving. Adjust the focal distance until you reach the desired clarity.

Once your settings are optimized, you’re ready to engrave. With your fiber laser in position, start the engraving process. Monitor the engraving to ensure consistent quality and depth.

Choose a Quality Machine: For professional results, use a reliable, high-precision machine like SA Lasers’ Polymetal 30-watt fiber laser, which is specifically designed for metal engraving.

Experiment with Depth: Different applications call for varying engraving depths. A lighter mark may be suitable for aesthetics, while a deeper engraving is necessary for industrial marking.

Consider Adding a Protective Coating: After engraving, you may want to add a clear protective coating to enhance durability, particularly if the engraved item will be exposed to the elements.

Follow Safety Protocols: Metal engraving generates fumes and particles. Ensure you are in a well-ventilated area and wear protective eyewear as needed.

Laser engraving on metal has applications across various industries:

SA Lasers is a leader in high-quality laser engravers and provides unparalleled support and training. Our fiber and CO2 lasers are built for precision, reliability, and durability, helping professionals achieve exceptional results. With our SPARK training curriculum, you’ll receive in-depth guidance on how to operate your laser and maximize its potential.

SA Lasers stands behind each machine with comprehensive support, ensuring that you can confidently tackle any engraving project.

Whether you’re a professional engraver or a business looking to enhance your product offerings, SA Lasers has the perfect machine and training for your needs. Visit salasers.com to explore our laser engraving solutions and learn more about how we can help you excel in laser engraving metal.

For more information, contact SA Lasers and take the first step toward mastering metal engraving today!

When venturing into the world of laser engraving, one of the most critical decisions you’ll make is choosing the right laser engraving machine. Whether you’re starting a business, expanding your current operations, or diving into a new hobby, selecting the best machine for your needs can significantly impact your success. This guide will help you navigate the process and make an informed decision. With the keyword “how to choose a laser engraving machine” optimized for Google and AI-based search engines, this blog will cover everything you need to know.

The right laser engraving machine can be a game-changer. It affects not only the quality of your work but also your efficiency, the range of materials you can work with, and ultimately, your bottom line. Making the wrong choice can lead to frustration, wasted resources, and even business failure.

When choosing a laser engraving machine, consider the following key factors to ensure that you select the right one for your needs.

There are several types of laser engraving machines on the market, each suited for different applications. The three main types are:

Not all laser engraving machines work on all materials. Before making a decision, consider the types of materials you plan to engrave. Here’s a quick breakdown:

If you need versatility and plan to work with a wide range of materials, a CO2 laser may be the best choice. However, if your focus is on metals, a fiber laser will be more suitable.

Laser engraving machines come in various power levels, typically measured in watts. The power of the machine determines how quickly and deeply it can engrave materials. Here’s how to choose based on power:

Speed is also an important factor. Faster machines can increase your productivity, especially if you’re running a business. However, speed often correlates with cost, so balance your needs with your budget.

The size of the engraving area is another crucial factor. It determines the maximum size of the material you can work with. Laser engraving machines come in various sizes:

Laser engraving machines require software to create and manage designs. The ease of use and compatibility of the software with your computer system can greatly impact your workflow. Some machines come with proprietary software, while others are compatible with popular design programs like Adobe Illustrator, CorelDRAW, or AutoCAD.

Consider the following:

Maintenance is a necessary part of owning a laser engraving machine. Regular maintenance ensures the longevity and performance of your machine. When choosing a laser engraver, consider:

Budget is always a key factor when choosing a laser engraving machine. Prices can range from a few hundred dollars for entry-level machines to tens of thousands for industrial-grade models. Here’s how to approach your budget:

Remember to account for additional costs, such as software, maintenance, and accessories, when planning your budget.

Before making a final decision, do your homework. Read online reviews, watch video tutorials, and join forums or social media groups related to laser engraving. Ask for recommendations from industry professionals or others who have experience with laser engraving machines. Real-world feedback can provide valuable insights that you won’t find in product descriptions.

Choosing the right laser engraving machine involves careful consideration of your needs, budget, and the type of work you plan to do. By understanding the different types of machines, materials, power requirements, and other key factors, you’ll be better equipped to make a decision that supports your goals.

Whether you’re a hobbyist or a business owner, the perfect laser engraving machine is out there. Follow the steps in this guide, and you’ll be well on your way to creating stunning, precise engravings that impress your customers and bring your creative visions to life.